The 3rd topic: Cracking resistant performance and self-healing

| In the past decades, fly ash has been used for massive concrete to resist thermal cracking owing to the low heat generation and higher deformability. Currently, the crack control of normal sized structures at early ages is also a topic of importance in the practice of engineering. It is, thus, required to clarify the method to maximize the high potential of fly ash concrete against cracking. The technical committee on fly ash conducted systematically arranged experiments on cracking caused by thermal actions and drying shrinkage to quantify the performance for the newly proposed design scheme, which was reported in the previous newsletter.

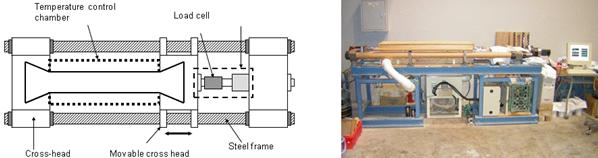

The committee reported three issues. One is the advanced performance of fly ash concrete against thermally induced cracking in comparison with normal Portland and blast-furnaces slab concrete. Although this is a sort of confirmation of past practical experiences with massive concrete, some scientific-backgrounds and the laboratory mock-up simulation are shown quantitatively to meet the challenge of performance-based design. Figure 1 shows the thermal cracking simulator to reproduce the stress and the state of confinement which may arise in real structures. The temperature history, magnitude of confinement and the strain hysteresis were differently reproduced and the time of cracking was measured for ranking the resistance of each concrete. The manual recommends applying thermal stress analysis to estimate the crack index to represent the risk of cracking in structures. The volumetric stability associated with the coupled autogenous and drying shrinkage is becoming a critical factor for material supply and structural quality control for both buildings and infrastructures. The fly ash concrete may have better deformability, but the early aged strength development is slow. |

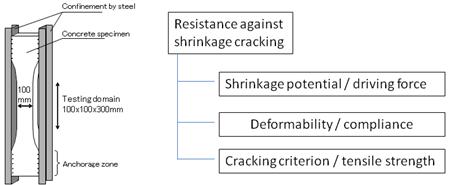

The overall performance of fly ash concrete, which is related to the reduced humidity in micro-pores, thus, has to be quantitatively clarified. As a matter of fact, recent reports of construction state the fairly controlled cracking of slabs and walls in some structures. The committee conducted a parametric study in experiments with the shrinkage confinement specimens as shown in Figure 2. The conclusions will be included in the design manual. The crack resistance of fly ash concrete against the volumetric contraction under confinement was found to degenerate when early aged curing is not sufficiently conducted. But, the suitable curing process codified by the JSCE standard specifications for concrete structures should be strictly applied; fly ash concrete performance on cracking was found to be equivalent to normal Portland cement concrete and a little higher than the blast furnace slag concrete. These data are compiled in the design manual for effective use of fly ash concrete.

The self-healing or self-sealing on water tightness is reported to definitely exist for fly ash concrete, although this high potential is not explicitly employed in any design code in practice. The self-healing is given by the Pozzolanic reaction of fly in the mixture. The committee could not quantify this high reliability and this long-term performance within the scheme of design. The recent progress and information of importance are, however, summarized in the manual published. Figure 3 shows the process of self-healing in which additional hydrate compound is being created among cracks and voids, and the gradual recovery of meso-scaled pores of concrete material is presented. The self-healing performance, which is more characteristic of fly ash, is expected to be quantified well controlled for effective use of fly ash in concrete. |

|

Figure 1 Temperature-Stress Testing Machine (TSTM)

Figure 2 Shrinkage restraint test and cracking

|

|

|

| Initial state | After deterioration | Self-healed |