| Readers' Voice Readers' voice from Dr. Le Quang Hung |

|

Director of National Bureau for Construction Quality Control, Ministry of Construction, Vietnam Vice President of Asian Concrete Federation Vice President of Vietnam Concrete Association |

|

It’s my honor to exchange some thoughts as a frequent reader of the Newsletter published by JSCE Concrete Committee. I can say that the Newsletter is very useful to readers who are dealing with concrete in their works as a designer, contractor, researcher, and planner or even as a student. It provides not only the information on recent activities of JSCE but also useful references for practical works and scientific research. In the latest issue (No. 20, Jan. 2010), I read the discussion between four Japanese experts on the topic “Overseas deployment of Japanese concrete technology: Issues and future”. This topic is very interesting to me as a person who has many chances to work and cooperate with many Japanese contractors and researchers. I would like to participate in the discussion by looking at this given topic from a different angle based on the actual situation in Vietnam. Honestly, discussing only on Japanese concrete technology may be too specific for me and other readers. I would rather discuss about Japanese construction technology in general. In international scientific communities, the contribution of Japanese engineers and researchers has been highly evaluated. For example, the leadership and contribution of Japan in such international communities like Asian concrete model code working group; Asian Concrete Federation, etc., are remarkable. In practical world, Japanese construction and consultant companies are doing great works all over the world. In Vietnam, Japan has been one of largest ODA (Official Development Assistance) contributor in recent years. In that context, Japanese contractors with great experiences and technologies have been working very hard and making great contribution to the infrastructure development of Vietnam. A typical example is the construction of Baichay Bridge (completed in December 2006), the world’s longest one-plane cable-stayed bridge crossing over the world-heritage Halong Bay. These infrastructures are making great contribution to the social economic development of Vietnam. Japanese technologies are highly evaluated by Vietnamese engineers. Another example is the Hai Van road tunnel (completed in 2005), the longest tunnel of this kind in Southeast Asia. Unfortunately, aside from the above-mentioned great achievements, there are still some serious problems of safety and quality that involve Japanese contractors when they carry out large projects in Vietnam. Recent examples are the collapse of a bridge during construction that killed 54 people and injured many others, or serious cracking problem of concrete structure in river crossing tunnel. To most of the people, there is no question about Japanese construction technology, but there is a great question about how such problems that hardly happen in Japan can befall on the famous and experienced Japanese contractors when they go abroad? It is important to carefully analyze the actual causes and withdraw important lessons from those mistakes to avoid similar situations in the future. One of the most important thing is to understand the local conditions including the difference in material, weather condition, workers’ skill, local engineers’ qualification, etc., and carefully consider those differences in planning, design, and construction. As a person responsible for construction quality, I do expect that Japanese advanced construction technologies will be further applied in important infrastructure development projects in Vietnam, such as high speed train (Shinkansen), national expressway, urban mass transportation network (metro), nuclear power plant, etc. I would like to discuss a little about application of Japanese standards in construction activities in Vietnam. |

For your information, Vietnam currently has more than 2000 construction-related standards and codes. Most of them are of Russian

origins since Vietnam have been strongly supported by Russia in development

of standards and codes. Recently, foreign standards like BS, ASTM, ASHTTO, JSCE, etc., are allowed to be used in construction projects in Vietnam as long as the safety, environment, and quality are appropriately considered. Regardless of the fact that many projects are carried out by Japanese contractors and consultants, the number of projects that applied Japanese standards is still very few. For example, ASHTTO standards are applied in design and construction even when those projects are carried out by Japanese contractors and funded by Japanese ODA. My understanding is that Japanese standards (issued by JSCE, JCI, JIS, etc.), which are crystallized products of Japanese technologies, are quite good and can be applied to such projects. I think there are some reasons why Japanese standards are not so popular abroad.

Obviously, Japanese technical standards also have many advantages as follows:

When discussing about Japanese concrete technologies, it is important to find out in which concrete-related technologies Japan are leading in the world. Then, more efforts should be given in promoting and introducing those technologies by all possible means. For example, Japanese can be proud of their advanced technologies in solving problems of thermal cracking countermeasure, non-linear analysis of reinforced concrete structure, nondestructive testing, seismic design, self-compacting concrete, etc. Another effective approach is to export the engineer qualification system in Japan to other countries, especially in Asian region where Japan is playing a leading role. I think no other country has done this important thing. Besides, it is also important to have national strategy and more political support to promote the Japan’s influence in terms of not only financial support but also the construction technology. I am looking forward to having more chances to work with Japanese engineers and researchers, exchanging information, knowledge, and experiences on concrete technology. I also expect to have more information about Japanese concrete technology through coming Newsletter of JSCE Concrete Committee. |

|

|

With best regards, Le Quang Hung Hanoi, April 20, 2010 |

||

|

|

||

Photo of Bai Chay Bridge |

||

|

|

||

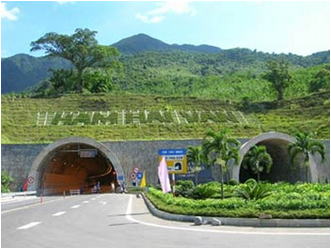

Photo of Hai Van Pass Tunnel connecting Thua Thien Hue and Da Nang Province in central |

||