The 4th topic: Placement related Performance Evaluation of Fly Ash Concrete

| Fly ash brings about fair concrete placement ability to fresh concrete

mixture, i.e., flows easily during placement and is stable against segregation

during and after placement. Fly ash is a mass of spherical-shaped fine

particles with specific surface area of more than 3000cm2/g. It is known

as a source of higher thixotropy. The aim of introducing this guideline

in this series of technical report is to quantify its performance for mix

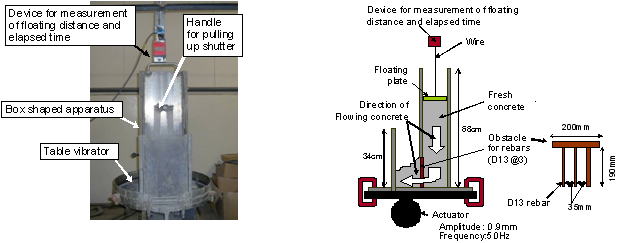

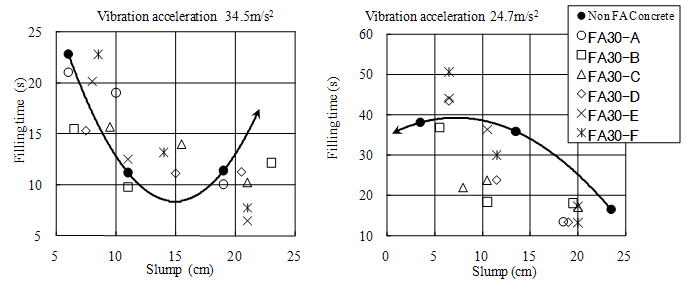

design of fly ash concrete. In view of workability, the task team focused on the filling time obtained from a fillability test conducted in a box-shaped apparatus (See Fig.1) placed on a table vibrator. There are three reinforcing-bar obstacles at the center gate surrounded by two boxes. Concrete is forced to flow through the center gate. The time when the floating plate falls down to 20cm is used as the characteristic index. First, fresh concrete is poured into the right side box up to the top. Second, the shutter is pulled up. At the same time, the apparatus is vibrated. From the engineering viewpoint, shorter filling time indicates fair compactability induced by vibration. The summary of slump versus vibration filling time is shown in Fig.2. The vibration acceleration of 34.5m/s2 was targeted for placing concrete into pre-cast units or forms of seismic-resistant RC members having large amount of steel. Another case of 24.7m/s2 was considered to be the placing at general sites. Tests results showed little difference among fly ash suppliers. The segregation of coarse aggregate and mortar during flow under vibration may lead to longer flow time. The |

arching of aggregates around the obstacles also prevents a smooth flow.

As a matter of fact, the filling time of fly ash concrete was less than

the ordinary concrete over 20cm of slump. This implies that fly ash concrete

had less arching risk. This is considered to the mechanism why fly ash

concrete exhibits higher workability especially in the case of high consistency.

Therefore, fly ash concrete is highly recommended for members containing

densely arranged reinforcement and/or pre-cast units. On the other hand, the filling time of fly ash concrete (less than 15cm of slump) takes longer under high energy vibration of 34.5m/s2. The viscosity is thought to be superior to its thixotropy. Here, it should be noted that the filling time of 24.5m/s2 of acceleration of fly ash concrete is smaller than that of the ordinary one over the range from 4cm to 24cm of slump. Fly ash concrete has good placing properties in all ranges of slump at ordinary sites. As a whole, fly ash creates higher workability of fresh concrete mixture as has been known since the past decades. But, its improved characteristics are quantitatively different site by site and design by design. When users select inappropriate combination of construction energy and density of steel in formworks, we cannot obtain the full potential of fly ash. The published manual may offer users a guideline on how to effectively select fly ash according to design and construction planning. |

|||

Fig.1 Overview of the box shaped-filling ability test on table vibrator

Fig.2 Effect of vibration acceleration on filling time of six fly ash concretes and ordinary concrete