| Report from Subcommittee on Increasing the Reliability of Nondestructive Testing Technology for Concrete (Subcommittee 339) | |

|

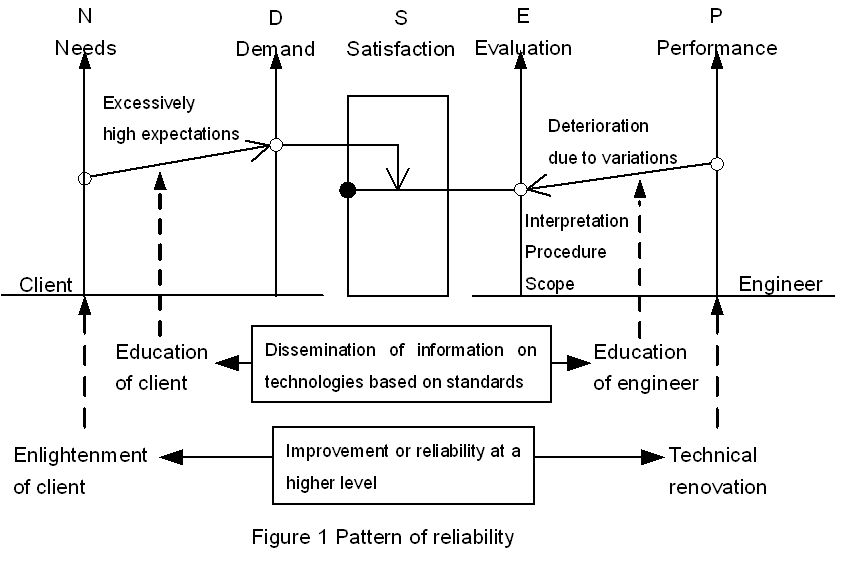

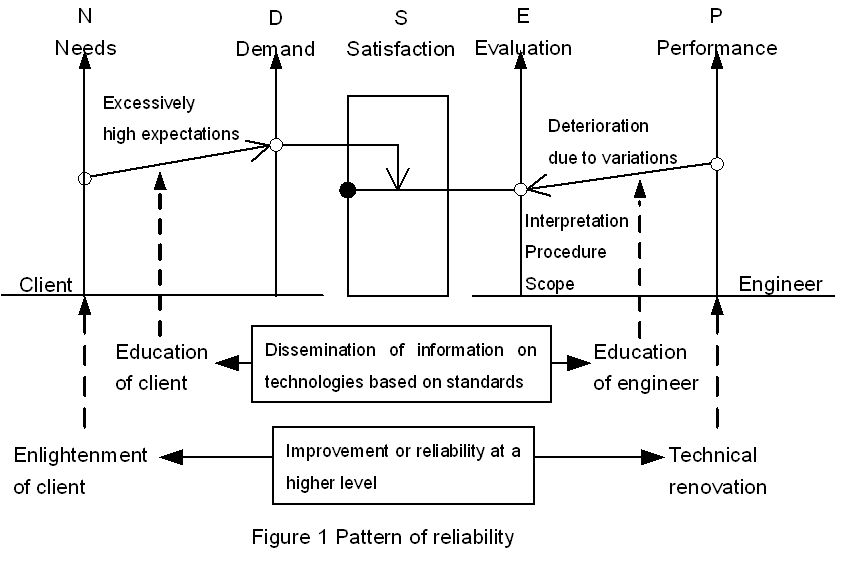

The subcommittee on increasing the reliability of nondestructive testing technology for concrete (Subcommittee 339) chaired by Professor Toshiro Kamada of Osaka University has been discussing the measures for increasing the reliability of nondestructive testing technology from two perspectives: education, and standards and specifications. This report introduces a pattern of reliability based on the client-engineer correlation as a highlight of research results investigated in subcommittee 339. |

| The reliability of nondestructive testing greatly depends on the satisfaction of the client with small variations of test results and other points. In the case of a low level of demand of the client, satisfaction is achieved even if the test results are not fully accurate or inadequate. Even if highly accurate results with small variations are obtained, the level of satisfaction is low (not as good as expected) as compared with the demand exceeding the results. Thus, one of the reasons for the loss of reliability of nondestructive testing of concrete is the gap between the excessively high expectations of the client and the technical level available. If the engineer is not sufficiently skilled and uses the method outside the designated scope of application or follows a wrong procedure or makes a wrong interpretation of results, the test results vary greatly. The variations deteriorate the reliability of results although some are caused by the technical level available or the variations of concrete materials. Variations of results are, however, relatively evaluated. Variations may sometimes pose no problems in the case where the demand for the accuracy or validity of results is low. When crack widths are required with a margin of error of plus or minus 10 cm, for example, a variation of 1 cm is not a problem. In the case where a margin of error of 1 mm is allowed, a variation of 1 cm is considered unreliable. In this study, therefore, "high level of satisfaction" is regarded as the "reliable state". | Figure 1 shows a pattern of reliability created between the client and engineer. Specific demand that the client presents to the engineer arises from the needs at a higher level. For example, in the case where there is a need to evaluate the soundness of a structure in terms of compressive strength, a demand is presented for knowing the compressive strength with a certain level of accuracy. The engineer, receiving the demand from the client, selects and implements a nondestructive testing method. Then, the capacity of estimating compressive strength varies according to the nondestructive testing method selected by the engineer. Even if an appropriate nondestructive testing method is selected, measurements vary greatly according to the skill of the engineer or engineer's interpretation of an appropriate procedure or scope of application of the method. The final results of nondestructive testing are therefore evaluated based on their accuracy or variations. Evaluated here are not the quantitative results of nondestructive testing but the qualitative results. When estimating the crack depth by a nondestructive testing method for example, the results may vary for technical reasons and further variations may occur according to the skill of the engineer. The qualitative reliability of the results is evaluated as the results of nondestructive testing. Finally, the satisfaction of the client is determined based on the balance between the evaluation of and the demand for test results. |

|

|

The terms used in Figure 1 are defined below. 1) Needs (N) Needs are the basic desire of the client and basically do not change. In the case where the client irrationaly demands compressive strength or other parameter for the purpose of evaluating the soundness of the structure, the needs may be changed by suggesting another appropriate parameter. It is assumed here that needs may be replaced through the "enlightenment of the client". 2) Demand (D) Demand is an expectation arising from the needs of the client. Demand may sometimes be represented by a specific figure related to accuracy or other parameter. In numerous cases, reliability is deteriorated as the client has a great expectation without understanding the technical level or the scope of application of the nondestructive testing. Then, the excessively high expectation may be optimized by presenting standards to the client or educating the client on standards. 3) Performance (P) This is the performance of a nondestructive testing method, which is enhanced only through technical renovation. It cannot be improved by standardization of nondestructive testing or education of the engineer. 4) Evaluation (E) This is the result of evaluation of nondestructive test results. Evaluation is made not of the test results but of the reliability of test results. The results of nondestructive testing generally vary according to the performance of the equipment or the skill of the engineer. The highest performance provided by a nondestructive testing method is rarely achieved and reliability is deteriorated to some extent. The result of evaluation can, however, be reinforced by reducing variations through the education of the engineer or standardization of the testing method. 5) Satisfaction (S) This refers to the satisfaction of the client, and is determined based on the balance between the evaluation E obtained by the nondestructive testing and the demand D of the client. The balance determines the level of reliability. |

Based on the above definitions, satisfaction (S) can be increased by several methods.

The first method involves the enhancement of performance (P). Technical renovation enhances

performance. Performance can be improved solely through technical renovation such as the

enhancement of equipment performance and the discovery of new principles. Even with no enhancement

of equipment performance, the performance of nondestructive testing can be improved by reinforcing

the skills of engineers and standardizing methods and providing uniform interpretations of test

results. The results of nondestructive testing vary according to the skill of the engineer.

Minimizing the amplitude of variations, making evaluations (E) properly and increasing measurement

accuracy are expected to improve the performance of nondestructive testing. Identifying the

appropriate technical level may help modify excessively high demand (D) of the client.

The needs (N) of the client can be changed through enlightenment by the engineer. For example,

replacing the needs for compressive strength for the purpose of determining soundness with the

needs for another parameter may enable the suggestion of a higher-level nondestructive testing

method fit for the parameter. The above discussions show that standards and specifications serve

as a basis for disseminating information on appropriate technical levels to the client and as a

means of standardizing procedures and interpretations and of optimizing the scope of application

for the engineer. Organizing standards and specifications and educating clients and engineers on

standards and making them familiar with standards are expected to improve the reliability of

nondestructive testing.

The above discussions suggest that identifying the scope of application and standardizing methods and providing uniform interpretations of test results for nondestructive testing enable the reduction of excessively high expectations of the client and of the variations of test results according to the skill of the engineer. |