In December 2009, the Concrete Committee of the Japan Society of Civil Engineers set up a subcommittee with 47 members under a chairman, Professor Koji Takewaka of Kagoshima University, to study on silicate-based surface impregnation method for concrete structures. Among several surface protection methods, the subcommittee focused its activity on silicate-based penetrants that are expected to improve properties of concrete surface layer, to heal cracks and to prevent deteriorations of concrete structures.

In the subcommittee, the following four working groups were set up to pursue the work for establishing guidelines not only on design and implementation method of the surface silicate-based impregnation method of concrete structures, but also test methods to evaluate performance of the penetrants;

| 1) |

Working group 1 (Coordinator: Toshiki Ayano (Okayama University), Vice-coordinators: Toshiya Maeda (Shimizu Corporation) and Hisashi Ando( Aston Corporation)): |

| / |

To work on idea of the composition and contents of the guideline |

| / |

To prepare the draft guideline based on information provided by the other working groups |

| 2) |

Working group 2 (Coordinator: Shin-ichi Igarashi (Kanazawa University), Vice-coordinators: Shin-ichi Miyazato (Kanazawa Institute of Technology) and Tetsuya Kudo (Radcon Japan Corporation)): |

| / |

To clarify the impregnation process and the reaction mechanism of silicate-based surface penetrants in concrete |

| / |

To quantify their ability to protect from various deteriorations |

| / |

To formulate drafts of testing methods for evaluating performance of penetrants |

| 3) |

Working group 3 (Coordinator: Susumu Moriya (Public Works Research Institute), Vice-coordinators: Kazuhiro Kasai (Tobishima Corporation) and Tatsuyuki Takashima (Ever Protect Corporation)): |

| / |

To develop the most effective implementation method of silicate-based surface penetrants onto concrete surfaces |

| / |

To clarify the effectiveness of its use with other repair methods as well as its applicable scope |

| 4) |

Working group 4 (Coordinator: Hidenori Hamada (Kyushu University), Vice-coordinators: Toshinobu Yamaguchi (Kagoshima University and Hideya Nishino (Fuji Kagaku Corporation)): |

| / |

To develop quality inspection methods on concrete after applying surface penetrant |

| / |

To establish verification systems to confirm continuity of surface treatment ability on concrete applied by the penetrants |

All groups completed their works in March 2012, then, the committee prepared a (draft) guideline which contents are as follows;

| Chapter 1 | General |

| Chapter 2 | Types of Silicate-based Surface Penetrants |

| Chapter 3 | Quality of Silicate-based Surface Penetrants |

| Chapter 4 | Design |

| Chapter 5 | Implementation Method |

| Chapter 6 | Inspection |

| Chapter 7 | Maintenance |

The main components of silicate-based surface penetrants react with calcium hydroxide, which is formed during the process of cement hydration, and form a C-S-H gel in the concrete. The main component used in commercialized penetrants is lithium silicate, sodium silicate, potassium silicate or their mixture. In the actual products, however, it is unusual to find just one of these ingredients; most of the penetrants contain various additives and minor ingredients that aim to stabilize reactivity of main components and to improve their physical properties. However, from an engineering point of view, it is little meaning to categorize silicate-based surface penetrants according to these additives and minor components. The subcommittee, therefore, proposed a classification of surface penetrants into two types, that are "Solidifying type" and "Reactive type", according to improvement mechanisms of the main components on concrete surface.

Fig. 1 Relationship between principal components and surface modification mechanism

The solidifying type of surface penetrant forms insoluble crystal under dry condition, which can fill pores in concrete, then the concrete surface is improved. The concrete surface impregnated with the penetrant, therefore, should be dry-cured after application. In contrast, the reactive type of penetrant dissolves in water and reacts with the calcium hydroxide in concrete. For this reason, wet curing of the concrete surface is necessary. They mean that the solidifying type and reactive one must be cured under opposite conditions, and a selection of the correct curing method is one of the most important requirements for reliable application of the penetrants.

Consequently, the draft recommendation discussed by the subcommittee includes a test method for distinguishing the type of the silicate-based surface penetrant, as an important part of the test methods. The test procedure to judge the penetrant type is briefly shown as follows;

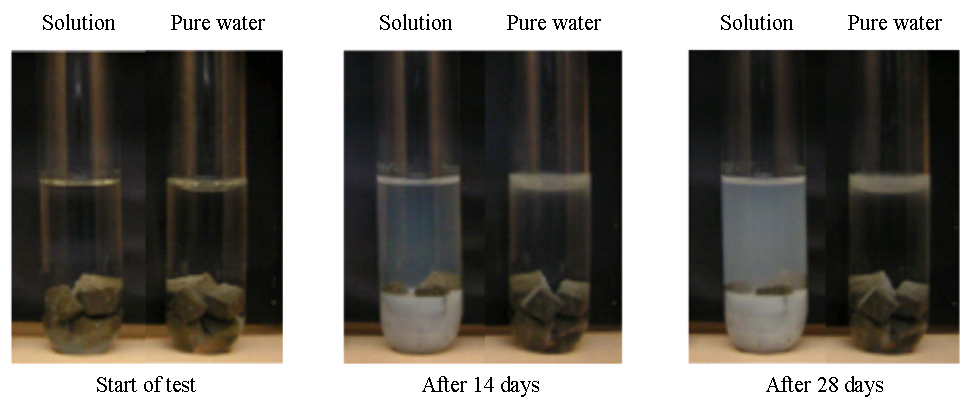

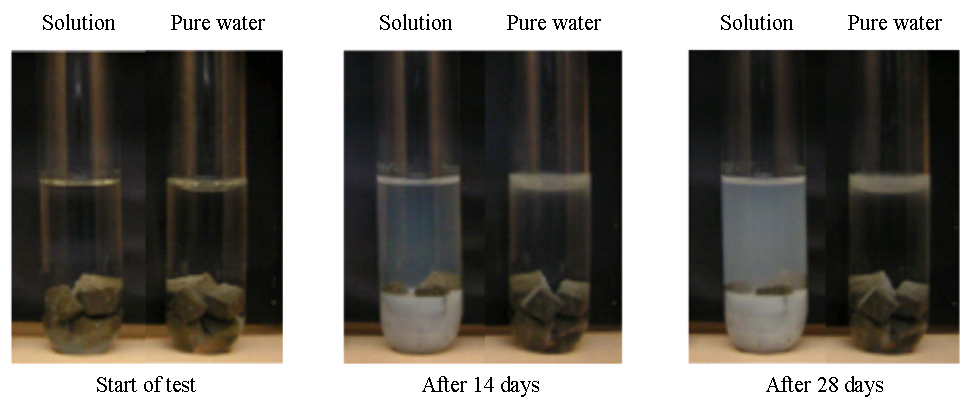

Fig. 2 Reaction testing of silicate-based surface penetrant

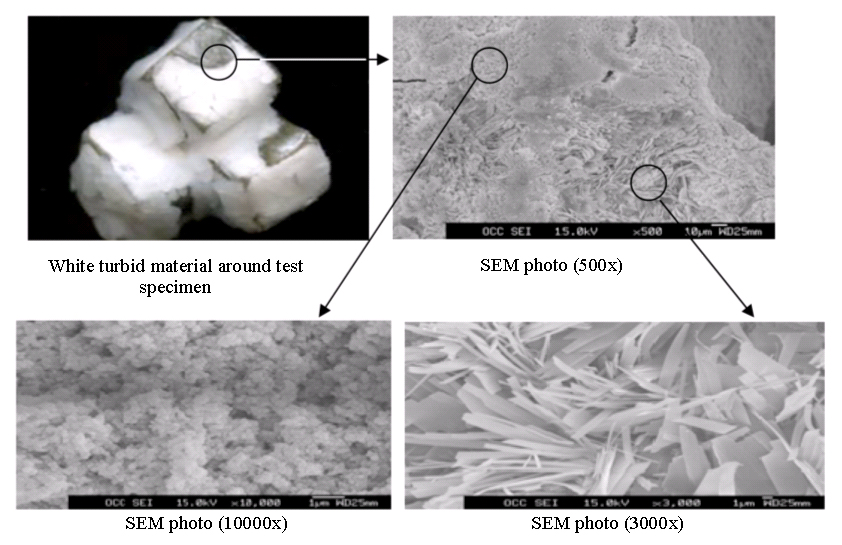

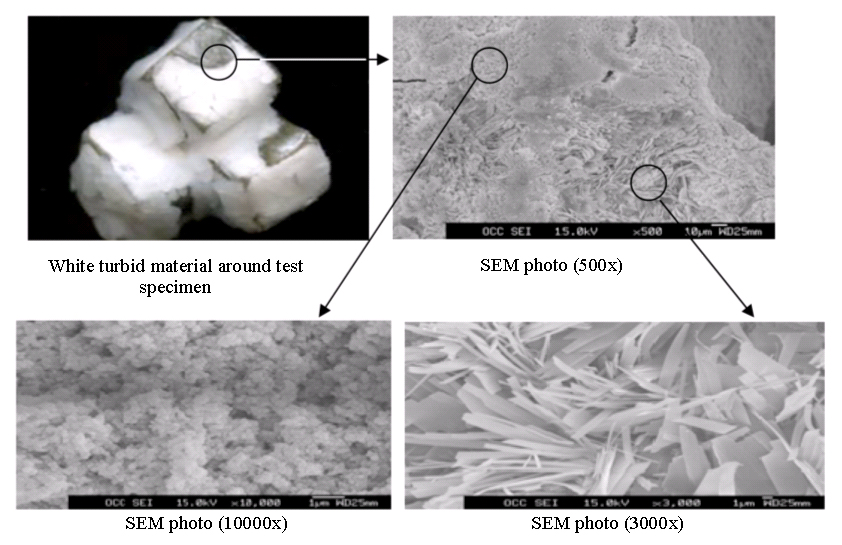

In the test procedure, a penetrant for test pours in water in which some pieces of cement paste brick are dipped. When there is not any change in the water after the several days have passed, the penetrant can be judged insoluble and is classified into the solidifying type. Those that easily dissolve in water and are observed to react with calcium hydroxide leached from the cement paste, as shown in Fig. 2 (see the result in the left), are classified as the reactive type. The photos in Fig. 3 are scanning electron microscope (SEM) images of the white turbid material shown in Fig. 2. It is mostly the chemical compounds containing C-S-H gel.

Fig. 3 SEM photos of white turbid material

The impregnation of concrete surfaces with silicate-based penetrants is expected to use widely on concrete structures for extending the service life of structures and their proper maintenance. However, for the reliability of this technique to be accepted by society in the future, it will be necessary for the penetrants applied on concrete surface to be carried out strictly in accordance with the specifications decided in the design process. Further, it will be important that the application records shall be kept and retained during a structure's life. The records can also be useful for carrying out follow-up investigations to ensure that the applied impregnation methods have functioned appropriately as it was designed.

The basic materials composing concrete structures can be designed and used according to a particular level of reliability based on vast amounts of design and construction data of the structures accumulated in the past. Comparing to these conventional design and construction perspectives, the verification methods concerning the performance of silicate-based surface penetrants, as shown in the draft guideline, may seem to comprise an excess of measures. However, in order that the surface impregnation methods gains the same trust as ordinary protection or repair ones, the designers and contractors shall be required to return to basic principles, then to carried out stringent design and implementation on the basis of the guidelines.

|