Subcommittee on Examination and Inspection Systems for the Design of Concrete

Mix Proportions Based on the Construction Performance of Fresh Concrete |

| 1. Introduction

Concrete construction has been undergoing drastic change due to the depletion of aggregate, the growing size of structures,

and the increasing density of steel reinforcement bars to improve earthquake resistance. Concrete with smaller water-cement

ratios and slumps has long been required for quality concrete structures, but to build high quality concrete structures,

the concrete also must have sufficient workability and the ability to be placed into every corner of the forms and around

the reinforcing steel. Concrete with extremely small slumps may produce honeycombs or cavities.

Concrete structures will perform as required only if the structures are properly designed, the concrete materials of

the required quality are properly mixed, and the concrete is appropriately applied. 2. Study on a Workability Examination System Working Group The Japan Society of Civil Engineers published “Recommendation for Mix Design of Fresh Concrete and Construction Placement-related

Performance Evaluation” to facilitate the use of concrete with appropriate slump according to

the structure’s construction requirements. The guidelines propose methods

for reducing the possibility of a poor filling caused by insufficient concrete

workability. However, the guidelines do not mention the actions or measures

to take during the design and planning stages to ensure appropriate construction.

Rather, the guidelines describe only actions to take during the construction

stage, with an emphasis on slump changes. Therefore, the guidelines pose

risks when using simple construction techniques that depend on slump changes.

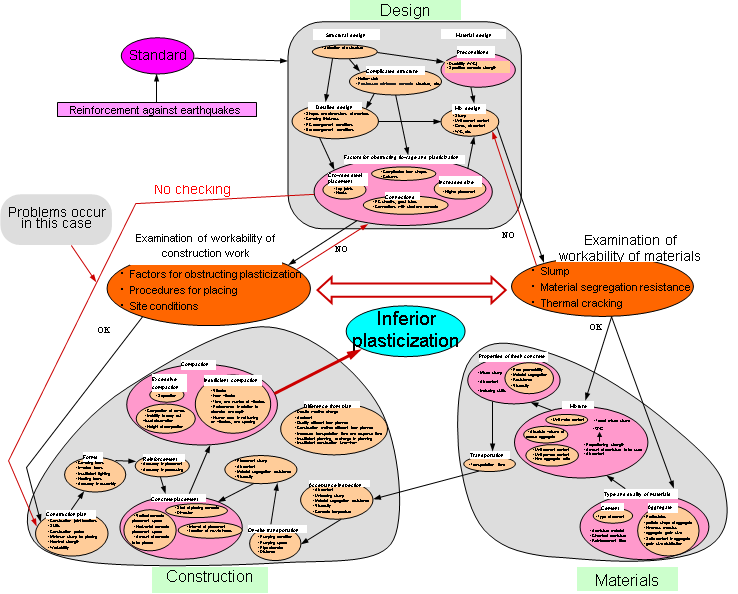

Therefore, this working group conducted a study on an ideal workability

evaluation system and proposed specific ideas for the system. (Figure 1)

3. Study on an Examination and Inspection Testing Method Working Group

Slump, as evaluated by slump tests, indicates the final change in length.

In this case, because only the dead load of fresh concrete is exerted on the concrete, only one aspect of workability is evaluated.

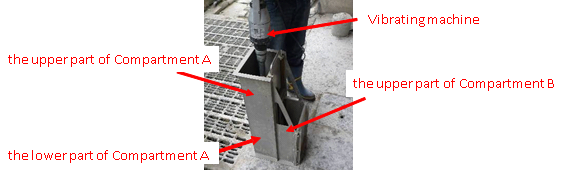

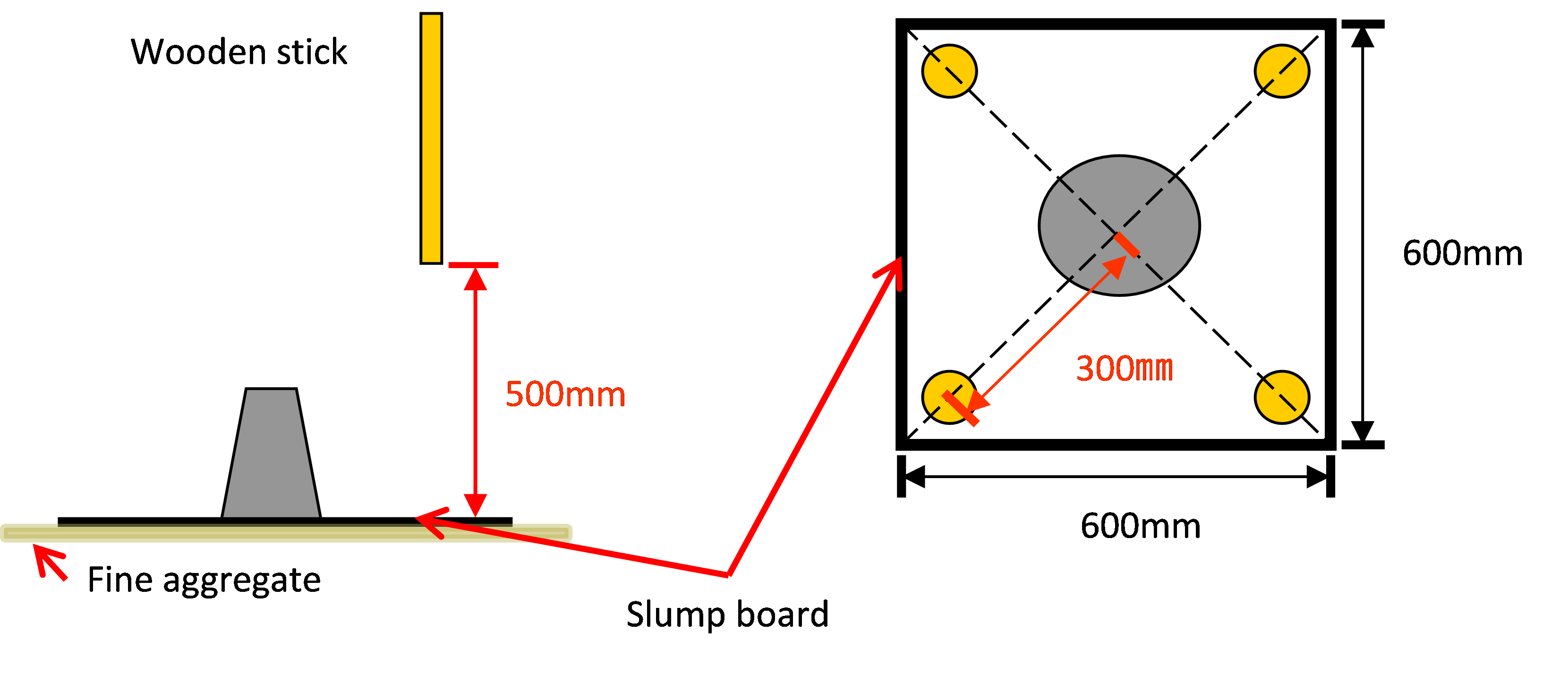

After summing up the present conditions and issues regarding slump, as described in section 2 above, this working group

examined documentation for a new evaluation and testing method and proposed a testing method using existing testing devices,

a box-type container, a long internal vibrator (Figure 2), and tamping tests (Figure 3).

|