1. Introduction

The JSCE-339 subcommittee was organized in September 2007. The subcommittee is chaired by Professor Toshiro Kamada from Osaka University. The purpose of the subcommittee is to enhance the reliability of non-destructive evaluation methods for concrete structures, which are utilized in the field of not only quality control and inspection of newly constructed concrete structure, but also maintenance of existing concrete structures.

In the first phase of the subcommittee, from 2007 to 2010, we investigated why the reliability of non-destructive methods for concrete structures was not sufficient compared with the requirement which was set by structures’ owners and managers. Based on intensive discussions about the relationship between the performance of non-destructive evaluation methods and the requirement, some proposals were made for the reliability enhancement from the viewpoint of the technical standards of non-destructive testing (NDT). Also, aiming to provide engineers with correct knowledge regarding non-destructive evaluation methods for concrete structures, the prototype of educational programs was proposed.

In the second phase of the subcommittee, from 2010 to 2012, we continued the investigation in order to build practical measures to enhance the reliability of non-destructive evaluation methods for concrete structures based on the results of our activities in the first phase. For the purpose, the subcommittee formed three working groups: Working Group for Studies on Qualification and Certification System for NDT Engineers, Working Group for Studies on Testing Devices and Field Measurements, Working Group for Studies on Visualization in Non-destructive Evaluation Results. The results of activities by these working groups are summarized as follows.

2. Committee activities

Working Group for Studies on Qualification and Certification System for NDT Engineers

One of the most important things in maintenance of concrete structures is to evaluate their deterioration conditions and residual structural performance by inspection and investigation. NDT is performed as a part of detailed inspection. Results of NDT are utilized based on technical standards of NDT and certification system of NDT engineers, dominating the reliability of non-destructive evaluation methods.

In Japan, technical standards of NDT for concrete structures are mainly established as NDIS (Non-destructive Inspection Standard) by JSNDI (The Japan Society for Non-Destructive Inspection). And, maintenance manuals of infrastructure maintenance using NDT are prepared by Japanese Government (Ministry of Land, Infrastructure, Transport and Tourism), JR (Japan Railway), NEXCO (Nippon Expressway Company Limited), and other managers. In this working group, the relationship between of the maintenance manuals and the technical standards are deeply examined in order to propose suitable contents of each manual and standard.

As for the certification system, major certifications for civil engineers are Professional Engineer certificated by Ministry of Education, Culture, Sports, Science and Technology, Registered Civil Engineer certificated by JSCE (Japan Society of Civil Engineers), and Concrete Inspector certificated by JCI (Japan Concrete Institute). In general, these certificated engineers are not specialists of NDT. For the purpose of enhancing the reliability of non-destructive evaluation methods for concrete structures, a new qualification and certification system for NDT engineer shall be established in the field of concrete engineering as well as existing certification systems above. In considering the new qualification and certification systems, the following points are paid attention to.

- Certificated by independent organizations

- Standardized definition

- Classification based on engineers’ level

- Estimation of knowledge and skill

- High level engineer needs practical experience

- Periodical renewal and re-certification system

- Conforming to international standard and specification

- Mutual certification system with other countries.

Working Group for Studies on Testing Devices and Field Measurements

An open experiment was held on December 1 and 2, 2011 at Public Works Research Institute. The purpose of this experiment was to evaluate the influence of operator skill level on accuracy of NDT. The target of the testing was to identify the bar-arrangement as well as the covering depth of concrete in concrete test pieces. Three types of test pieces were used; a small calibration block (150mm x 150mm x 500mm), a floor slab (300 mm x 1500mm x 2500mm) and a large box structure (2900mm x 2600mm x 4100mm). Sixteen operators with different skill levels ranging from beginners to professionals with more than twenty-five-year experiences participated in the experiments. The electromagnetic radar method and the electromagnetic induction method were used as the nondestructive testing methods. The results of the experiment are summarized as follows.

- When applying the electromagnetic radar method, the accuracy of the measurements decreased as the depth of the bars increased. However, the relative errors were proportionally lower for test pieces at greater depths than at shallower depths. This was true regardless of skill levels.

- As for the electromagnetic induction method, the accuracy followed the same pattern with the accuracy decreasing with depth. However, in contrast to the electromagnetic radar method, the relative errors were proportionally higher for test pieces of greater depths than shallow ones. This was true regardless of skill levels.

- The experience period of operators seems to have little to do with the measurement accuracy. However, the presence of certification and qualification of operators improved the accuracy much better.

Working Group for Studies on Visualization in Non-destructive Evaluation Results

To obtain the reliability of non-destructive evaluation methods for concrete structures, firstly the results should be accurately interpreted by an inspector, and then the interpretation should be appropriately delivered from the inspector to the client. When the result is not interpreted properly by the inspector, the reliability of the test may decrease even if the results are obtained accurately. Moreover, the reliability is not secured even if we have accurate results and proper interpretation but the interpretation is not delivered to the client clearly. This means that the reliability of non-destructive evaluation methods finally depends on the understanding of the client even if the inspector clearly understands the results. Visualization is not only the tool for the inspector to evaluate the results properly, but the tool for the client to understand the interpretation clearly.

In this working group, visualization of results from non-destructive testing was discussed with consideration of these two points. As a result, it is clarified that there are two purposes of the visualization such as to evaluate the results accurately and to have clear understanding between the inspector and client. It is also noted that visualization is the interpretation way strongly depending on the inspector and the proper threshold or expression of the results is subjectively determined by the inspector. This leads to the fact that the results are likely to be biased if the proper interpretation is not attained or the proper threshold is not determined due to subjective judgment by the inspector.

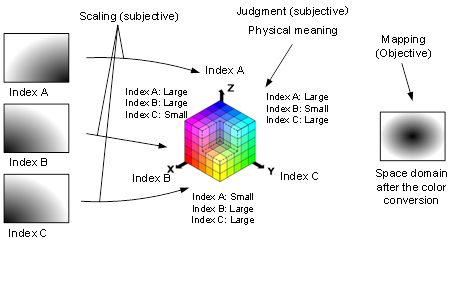

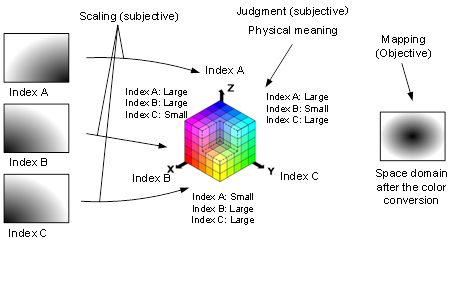

One of the technical issues on visualization is how to simultaneously express several and different information at the same time. To resolve this problem, we proposed two visualization methods using multiple colors: one is to use two axes and the other is to use three axes in the visualization. In every method, it is necessary to determine the proper threshold for every index when the data are merged, and also to properly give some physical meanings to the colors. The proposed method might not increase directly the understanding of inspector or client, but finally the process of the interpretation which has been done implicitly is clarified through the discussion on the proposed method.

Visualization using three axes to express three indices at the same time

3. Future Activities

Through the enthusiastic activities of the subcommittee, useful and practical fruits were obtained as mentioned above. However, it is necessary to enhance the reliability of non-destructive evaluation methods for concrete structures much more in order to utilize NDT more widely. The following matters should be investigated from now on.

- Integration of individual NDT techniques, and their standardization

- Systemization of maintenance technologies including residual performance evaluation based on NDT results

|