1. Characteristics

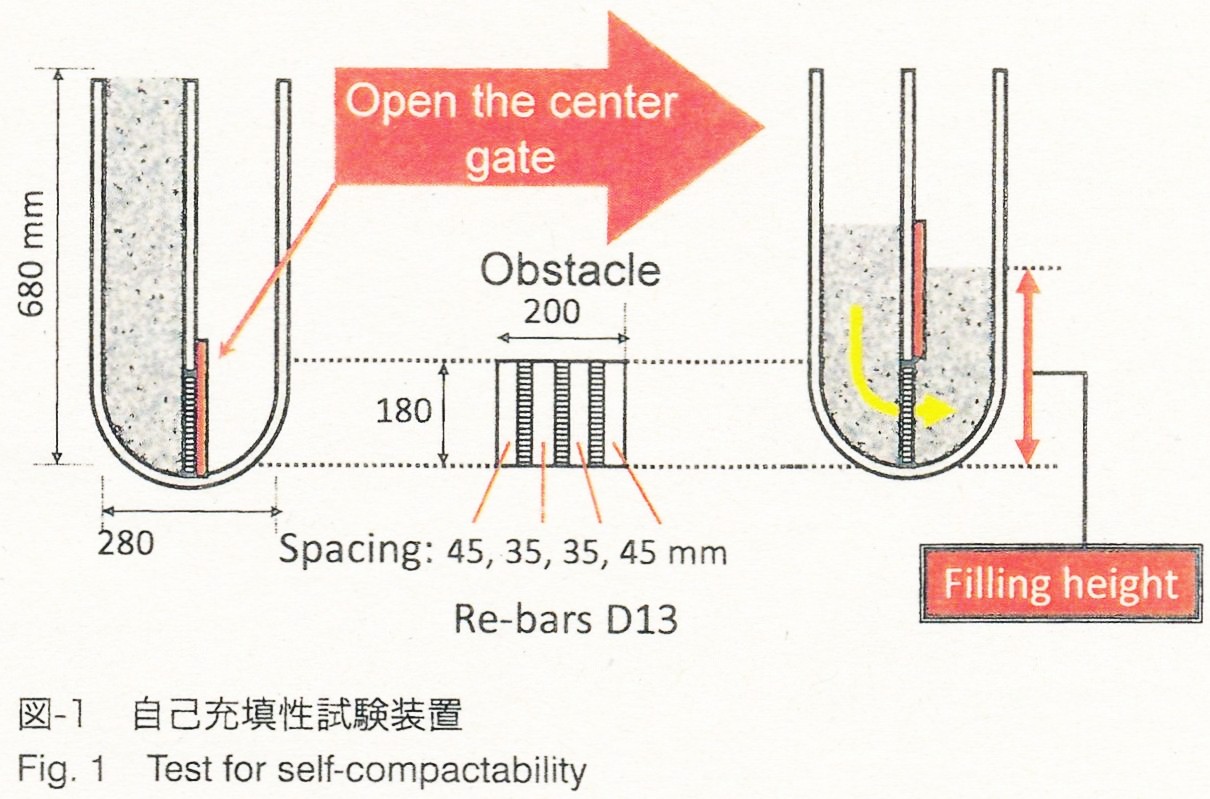

Self-compacting high-performance concrete is a high performance concrete that can be compacted into every corner of a formwork, purely by means of its own weight and without the need for vibrating compaction (Fig. 1). This concrete is defined as follows at the three stages of concrete: (1) Fresh: self-compactable; (2) Early age: avoidance of initial defects; (3) After hardening: protection against external factors.

2. History of development

To make durable concrete structures, sufficient compaction by skilled workers

is required. However, the gradual reduction in the number of skilled workers

in Japan’s construction industry has led to a similar reduction in the

quality of construction work. A solution for the achievement of durable

concrete structures independent of the quality of construction work is

the employment of self-compacting concrete. The necessity of this type

of concrete was proposed by Okamura in 1986. Studies to develop self-compacting

concrete (SCC), including a fundamental study on the workability of concrete,

were carried out by Ozawa and Maekawa at the University of Tokyo. The prototype

of self-compacting concrete was first completed in 1988 using materials

already on the market. The prototype performed satisfactorily with regard

to drying and hardening shrinkage, heat of hydration, denseness after hardening,

and other properties. At almost the same time, “High Performance Concrete”

was defined as a concrete with high durability due to low water-cement

ratio by Aitcin et. al. Since then, the term high performance concrete

has been used around the world to refer to high durability concrete. Therefore,

Okamura adopted the term “Self-compacting High Performance Concrete” for

Japan’s SCC.

3. Mechanism for the technology

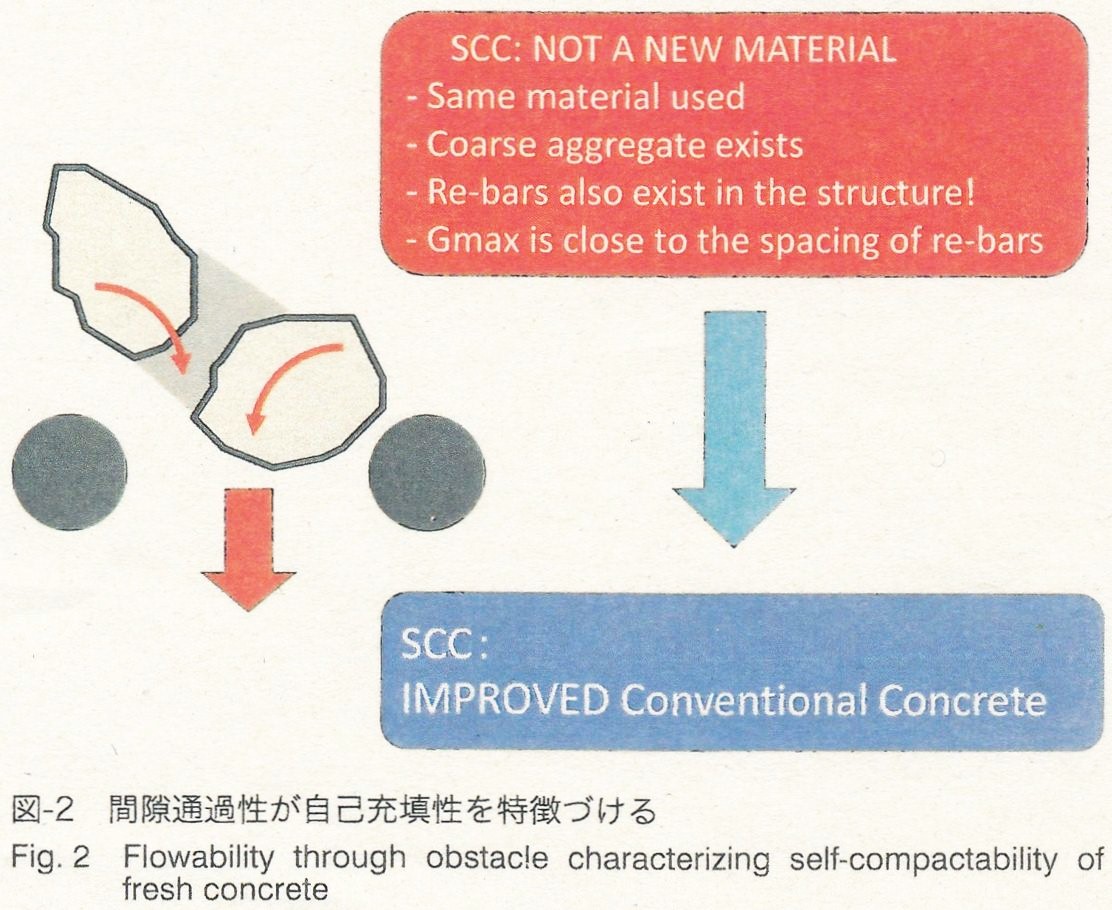

The self-compactability of fresh concrete depends mainly on its ability

to flow through obstacles[1] (Fig. 2). The method for achieving self-compactability

involves not only high deformability of paste or mortar, but also resistance

to segregation between coarse aggregate and mortar when the concrete flows

through the confined zone of reinforcing bars. Okamura and Ozawa have employed

the following methods to achieve self-compactability: (1) Limited aggregate

content; (2) Low water-powder ratio; (3) Use of superplasticizer. Highly

viscous paste is required to avoid the blockage of coarse aggregate when

concrete flows through obstacle. When concrete is deformed, paste with

a high viscosity also prevents localized increases in the internal stress

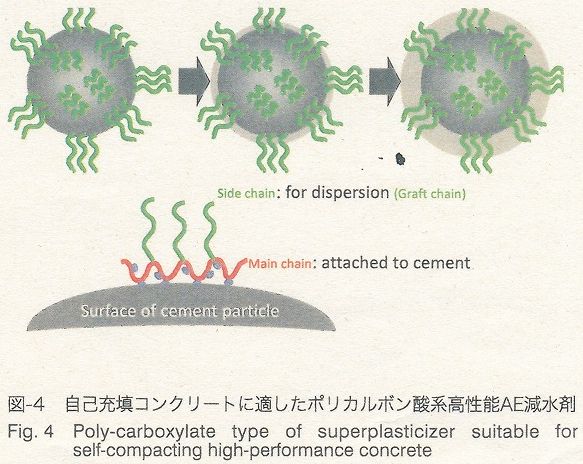

due to the approach of coarse aggregate particles (Fig. 3). High deformability

can be achieved only by the employment of a superplasticizer, keeping the water-powder

ratio to be very low value. Poly-carboxylate type of superplasticizer is suitable

for SCC (Fig. 4).

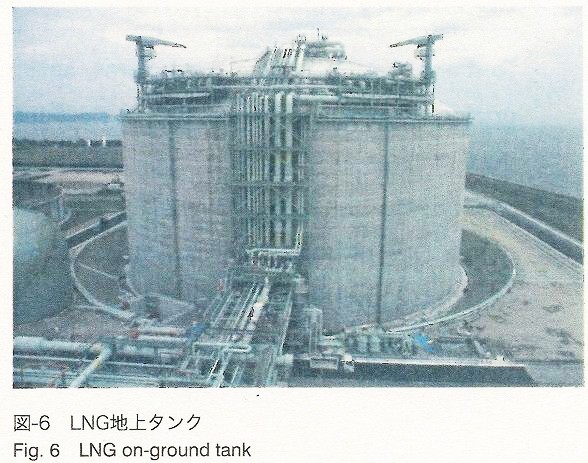

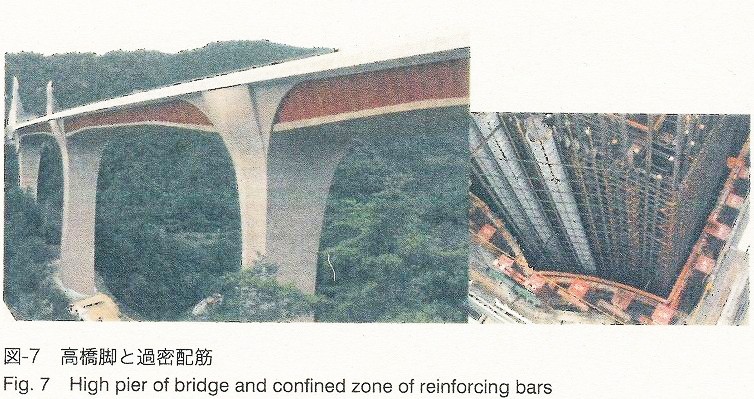

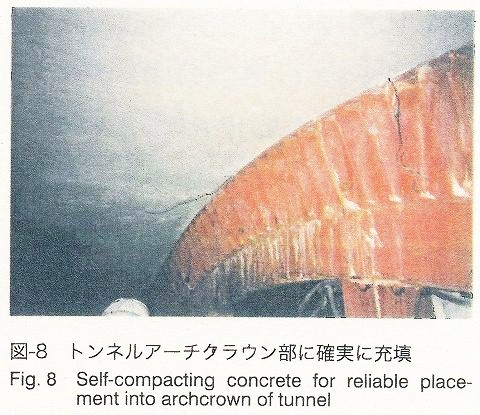

4. Practical applications

Self-compacting concrete has been used in many practical structures since

1990. Currently, the main reasons for the employment of self-compacting

concrete can be summarized as follows: (1) To shorten construction period

(Fig. 5); (2) To assure compaction in the structure: especially in confined

zones where vibrating compaction is difficult (Fig.s 6 and 7); (3) To eliminate

noise due to vibration: effective especially at concrete products plants.

Also, SCC is applied to tunnel lining for preventing the cold joint (Fig.

8).

Reference

[1] Ouchi, M. State-of-the-art report on self-compactability evaluation, Proceedings of the international Workshop on Self-Compacting Concrete (CD-ROM), Kochi, Japan, March 1999, Also available from Concrete Engineering Series, No. 30, Japan Society of Civil Engineers, March 1999.