Dr. Hiroi began developing innovative civil engineering techniques and theories including a formula for calculating the wave force acting on a breakwater, a method of oblique stacking of concrete blocks for the breakwater body, and the mixing of volcanic ash for strengthening concrete. Among them, the long-term durability tests of concrete that he initiated[1,2] are worthy of special mention.

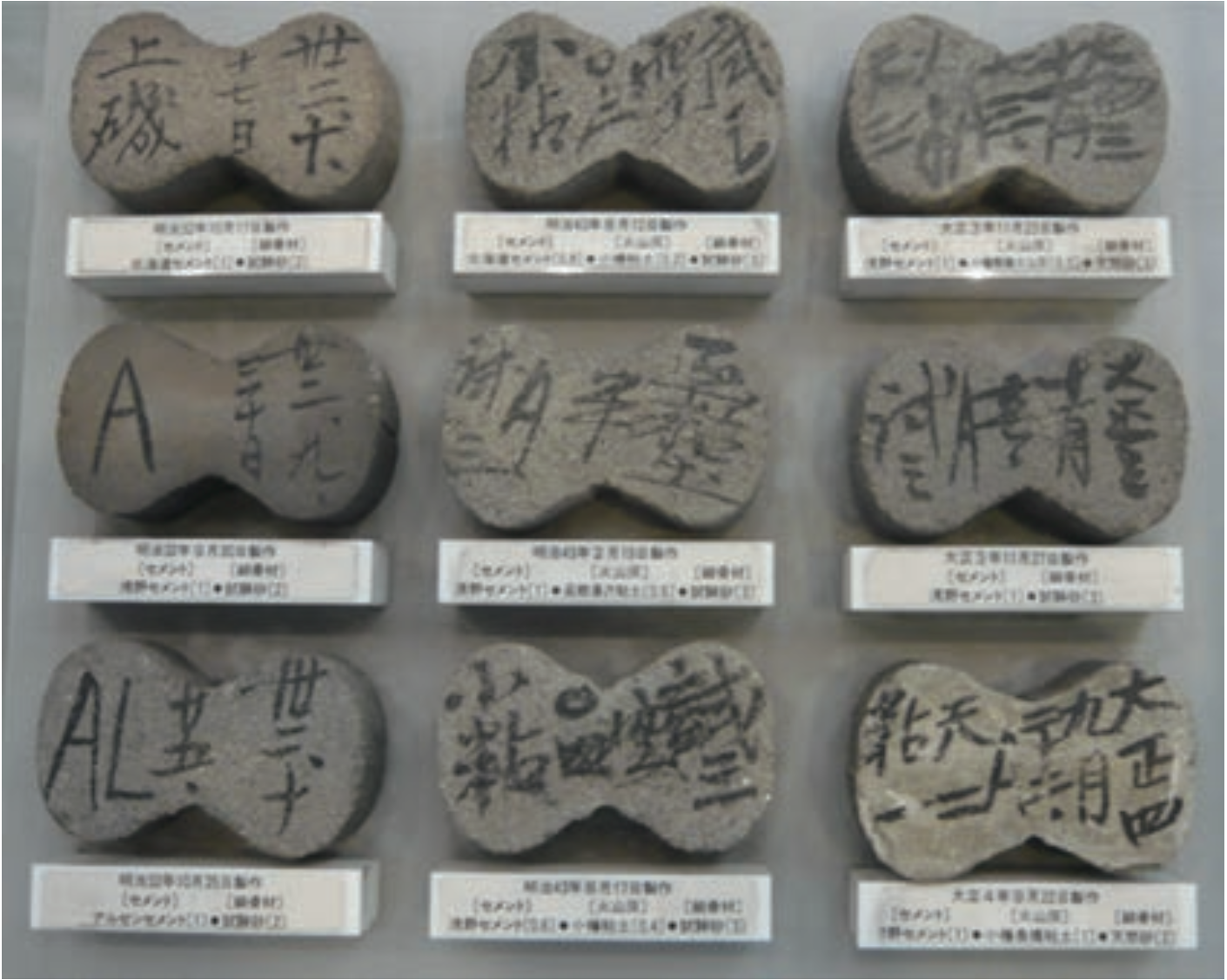

The objectives of the test were to determine mix proportions and to evaluate the durability of the concrete to be used for the breakwaters. Dr. Hiroi started producing gourd-shape test pieces (the mortar briquettes shown in Fig. 1) for use in tensile strength tests. The test method entailed applying a tensile force by pulling on the two ends of the test piece. Production of the mortar specimens started in 1896, a year before the project began, and continued for 40 years until 1937, when Mr Chouemon Ito, 2nd Head of the Office, took over the work. The following test parameters were implemented: 13 kinds of cement produced by different manufacturers; 19 kinds of volcanic ash (different kinds and locations); 10 kinds of fine aggregate (different locations); and 4 kinds of mixing water (seawater, salted water, and two fresh water). The total number of test pieces reached approximately 60,000 of 491 varieties, of which about 4000 still remain for future tests. It can be inferred that Dr. Hiroi originally intended to carry on testing for 50 years. However, another series of tests was started during Taisho Period (1912-26), so the test became called the “100-year durability test” somewhere down the line.

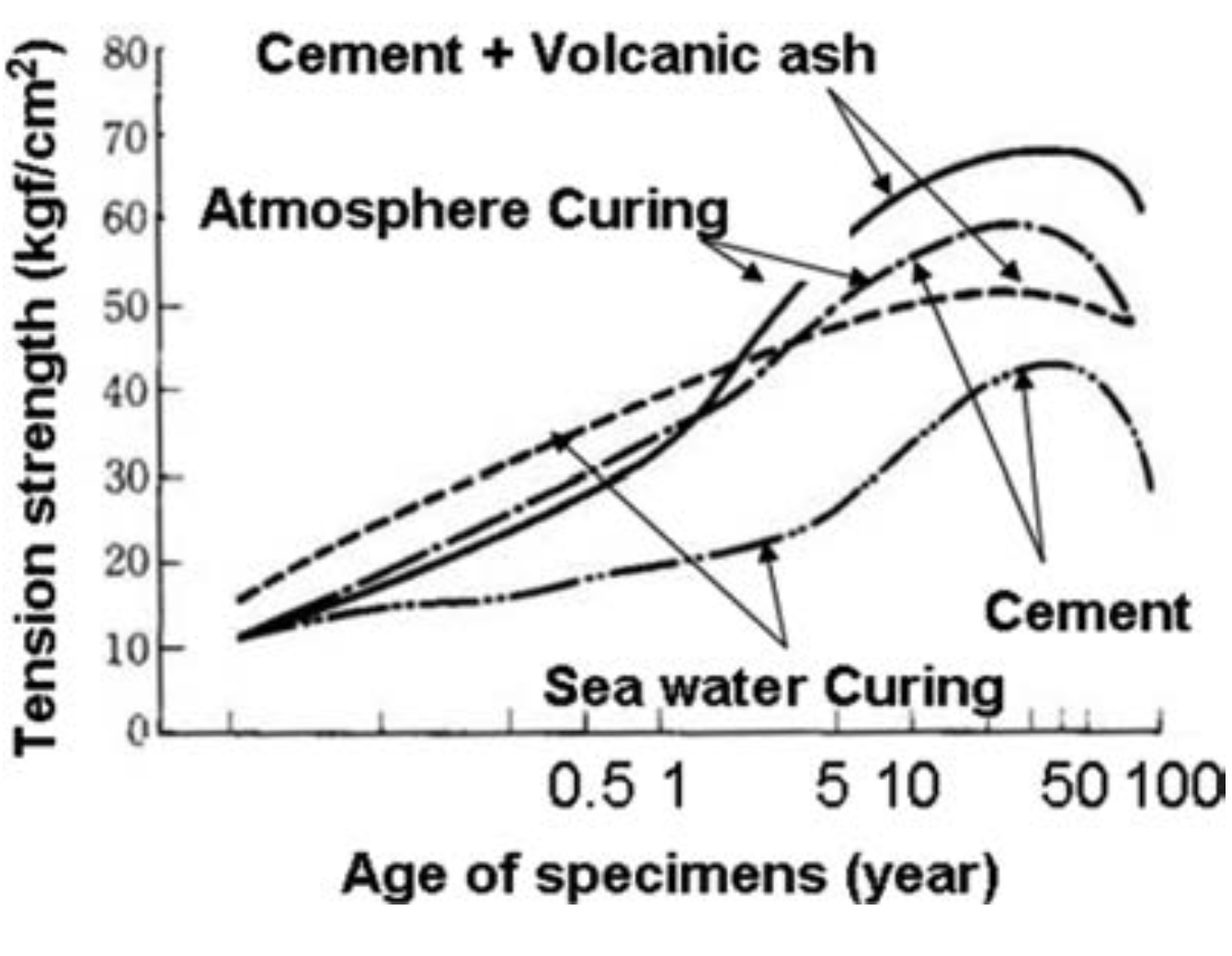

Figure 2 shows the results of the 100-year durability test to date with four different principal test parameters: with and without volcanic ash and curing conditions. The results show that the strength is greatest with atmosphere curing. Test specimens cured in the atmosphere exhibit smaller variations in strength whether with or without volcanic ash, while those cured in seawater with volcanic ash tend to become strong earlier. Since mortar with volcanic ash has higher strength than that without, this proves that volcanic ash contributes to enhancing concrete durability in seawater. Though a decline in strength is found after 30-50 years, one of the reasons for this may be considered to be an interruption of the planned curing regime due to world wars. Further examination and discussion of this point are needed.

| [1] | Otaru Port Construction Office, Hokkaido Development Bureau: Outline of the 100-Year Durability Tests of Concrete Conducted at Otaru Port. |

| [2] | Sarukawa, Y., Sakai, K. and Kubouchi, A.: Japan’s 100-Year-Long Otaru Port Breakwater Durability Test, Concrete International, 16(5), 25-28, 1994. |