Tetsuo HARADA (Nagasaki University), Yasukiyo IKUTA (Oshima Shipbuilding), Kenji SASAKI (Nagasaki University), Hiroshi OHATA (Ube Industries), and Myokin TOKUYAMA (Daiichi Institute of Technology)

The authors have developed a new anchorage method for continuous fiber reinforcing materials such as carbon fiber reinforced polymer (CFRP) strands using a highly expansive material (HEM). Experiments have confirmed that this method offers great utility for anchoring tendons of both steel strands and CFRP strands in prestressed concrete (PC). The new anchorage method offers the following features: (1) solid adhesion of various FRP/steel tendon types; (2) no stress concentration at point of adhesion due to uniform expansive pressure, which acts similarly to a fluid and can reach up to 50 MPa; (3) sustained prestressing force over the long term with negligible loss over time.

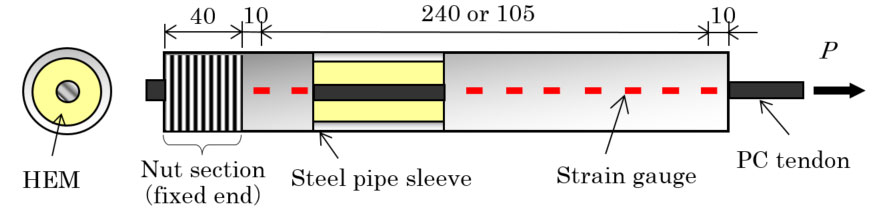

Fig. 1 Anchorage device using HEM

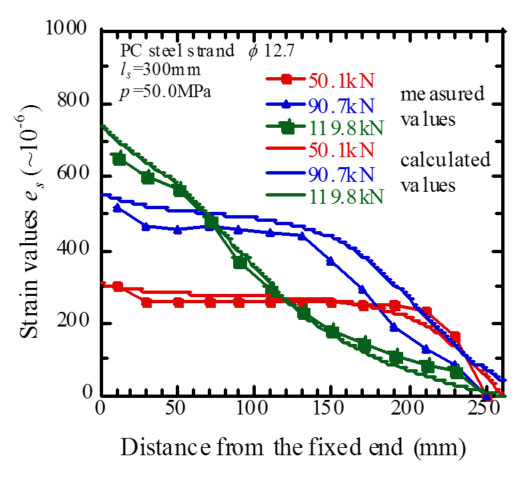

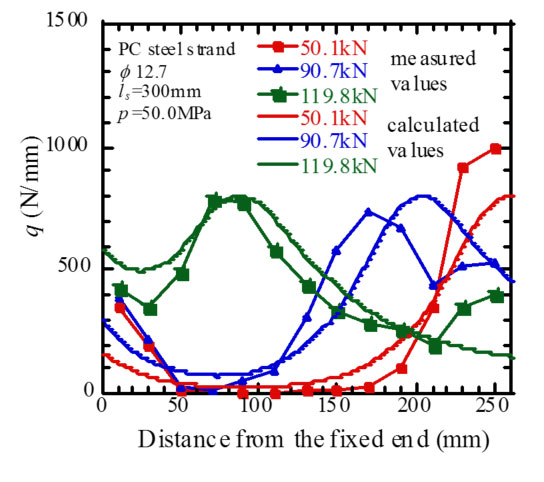

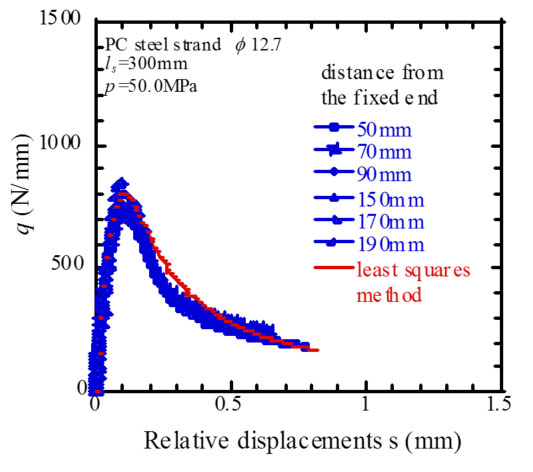

Figure 1 shows the test specimen used in the confirmation experiments. Once the gap between the steel pipe sleeve and the prestressing tendon has been filled with the HEM, the configuration resembles a shear spring, with shear force q per unit length. The tensile force acting on the prestressing tendon is transferred to the steel pipe sleeve. The locking nut on the steel pipe sleeve ensures the tendon is fixed firmly. Tensile loading tests with CFRP strands and steel strands secured using HEM anchors were carried out. Figure 2 shows the strain distribution on the steel pipe surface for the case of a steel prestressing tendon with several expansive pressures. Figure 3 shows the distribution of q values obtained by calculation using measured strain values taken from Figure 2. The relative displacement s at an arbitrary position x along the sleeve is the difference between the tendon displacement wp and the steel pipe sleeve displacement ws, as determined by integrating the measured strains from the fixed end to position x. The relationship between q and s is shown in the form of q-s curves in Figure 4. The main feature of this relationship, that the curve is substantially the same regardless of distance x from the load end, derives from the uniform action of the expansive pressure.

Fig. 2 Strain distribution

Fig. 3 Distribution of q values

Fig. 4 q-s curves

Based on these experimental results, the HEM anchoring mechanism was investigated using shear transfer mechanics. Nonlinear simultaneous differential equations were introduced assuming that the HEM layer behaves as a shear spring, and numerical analyses were carried out using the q-s curves. It was found that this analytical method was very effective, giving simulation results that agree well with the experimental results as shown in Figures 2 and 3.

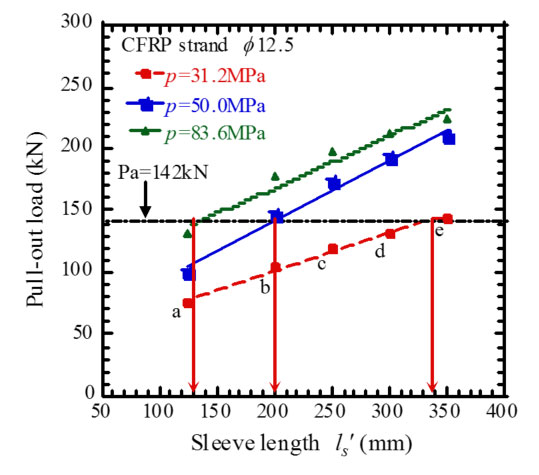

Additionally, by testing until failure of the CFRP strands (and the yield point of the steel strands), the relationship between length of steel sleeve and pullout load was clarified for various expansive pressures, as shown in Figure 5.

Fig. 5 Sleeve length determination methods

The authors hope that this HEM anchorage method will contribute to reducing the maintenance and increasing the longevity of PC structures.