Hai Van Tunnel Construction Project

During The Vietnam War, the lifelines connecting the North-South national corridor was destroyed completely. The Vietnamese Government, “Socialist Republic of Vietnam”, after united into one nation, started the reconstruction of those lifelines soon after the ending of the war time. The Japanese Government resumed the Japanese ODA in 1992 and both road and railways had been reconstructed for decades under the ODA scheme, accordingly the national economy had been recovered and logistic volume were increasing along National Route No.1 (NH1) which connects the capital city between Hanoi and commercial capital Ho Chi Minh City along the coastal line of Vietnam.

The “Hai Van Pass” is the biggest traffic bottleneck on NH1. More than ten times of fatal traffic accidents occurred within one year, because of steep grade with small radius pass road, and the pass road had been closed because of those traffic accident many times in one year.

Hai Van Tunnel Construction Project, was formulated, in cooperation of The Vietnamese and Japanese Governments, for overcoming such traffic bottleneck and it was one of the best symbolic construction projects that demonstrating the economic growing of the country in 1990s.

The project was completed in time successfully. Not only the contribution of development of the national economy but also Japanese tunneling technologies were transferred to Vietnam and Vietnamese construction contractors acquired the tunnelling technologies at the level of doing by themselves.

Through the project implementation, all engineers were enjoying the cooperation in the construction works, not only civil works but also mechanical and electrical works as well. After the opening ceremony, the friendships built during the project had been closely maintained and many times of “Reunion Parties” are being held to date.

1Introduction

1.1Project Background

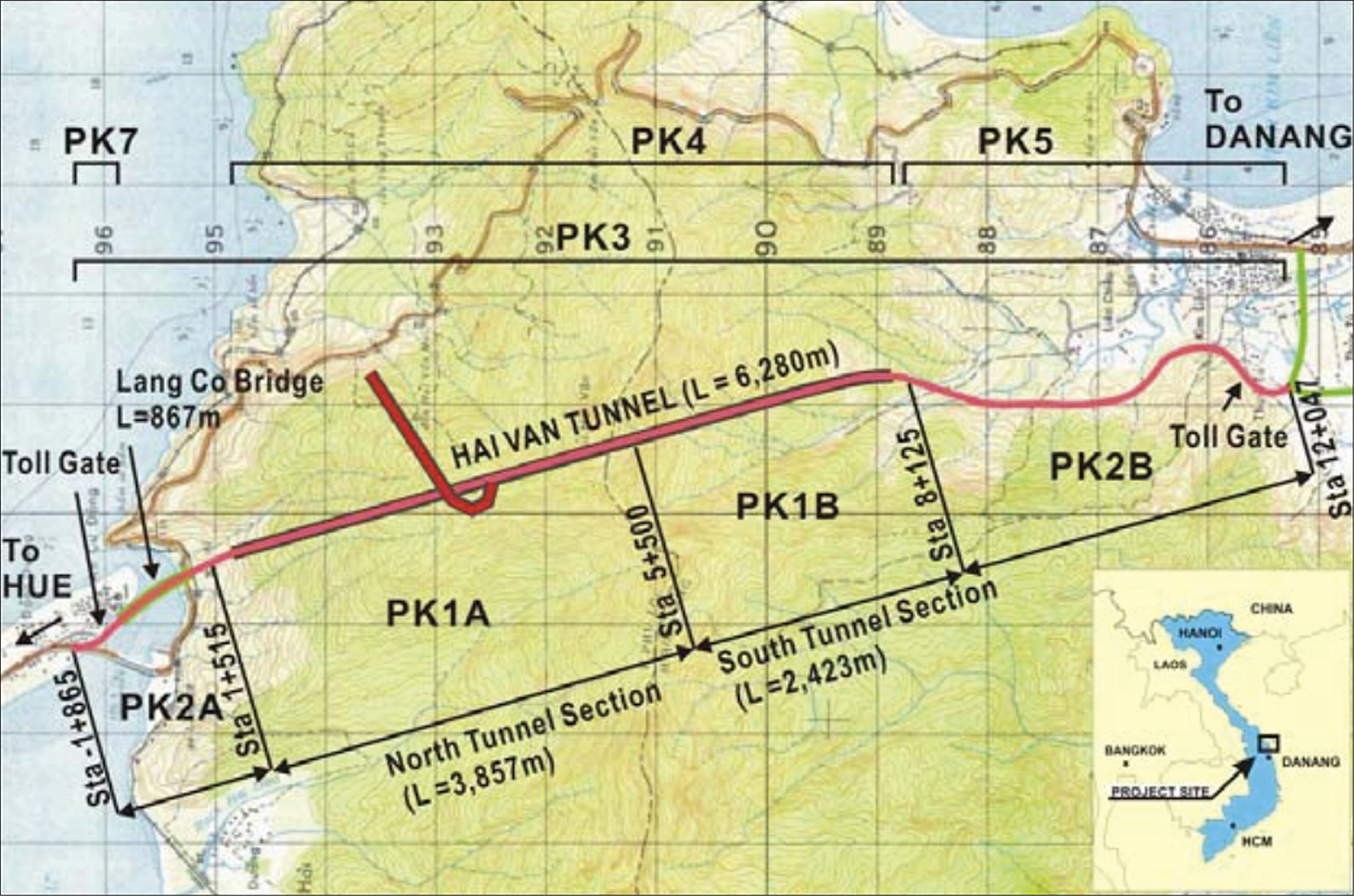

The Hai Van Pass located in coastal Central Vietnam, is the biggest traffic bottleneck on the National Route No.1, which is the most important north-south arterial linking the capital Hanoi with Ho Chi Minh. That Pass is to an elevation of 475 m for approximately 20 km with continuous small curves and steep grade. From the late 1990’s, the rapid development of the national economy has increased the logistic volume through the pass; however, the heavy tracks has been forced to run slowly and fatal traffic accidents increased year by year. In addition, the road is often blocked due to landslides and slope failure during the rainy seasons. Under such circumstances, the Vietnamese Government decided to construct a new highway segment with a tunnel under the Hai Van Pass by the Prime Minister’s Decree in March 1994 (Figure 1).

1.2Traffic Safety Benefits by the Project

The Hai Van Pass was infamous for a “traffic bottleneck” because traffic jam had frequently occurred, and road-closure happened almost once a month. Moreover, many motorcyclists have caused fatal accidents when they travel on the downslope of the pass. The opening of the Hai Van Pass dramatically improved the traffic safety of the pass road (Table 1).

| Year | # of Major Accident | Fatal | Injured | Road Closure |

|---|---|---|---|---|

| 1996 | 14 | 6 | 20 | 28 |

| 1997 | 9 | 4 | 24 | 29 |

| 1998 | 14 | 10 | 35 | 33 |

| 1999 | 17 | 13 | 14 | 30 |

| 2000 | 32 | 5 | 57 | 29 |

| 2001 | 19 | 6 | 16 | 26 |

| 2002 | 16 | 4 | 7 | 53 |

| 2003 | 26 | 5 | 10 | 55 |

| 2004 | 31 | 9 | 16 | 62 |

| Toral | 178 | 62 | 199 | 345 |

| Ave. | 20 | 7 | 22 | 38 |

2Project Chronology

2.1Consulting Services

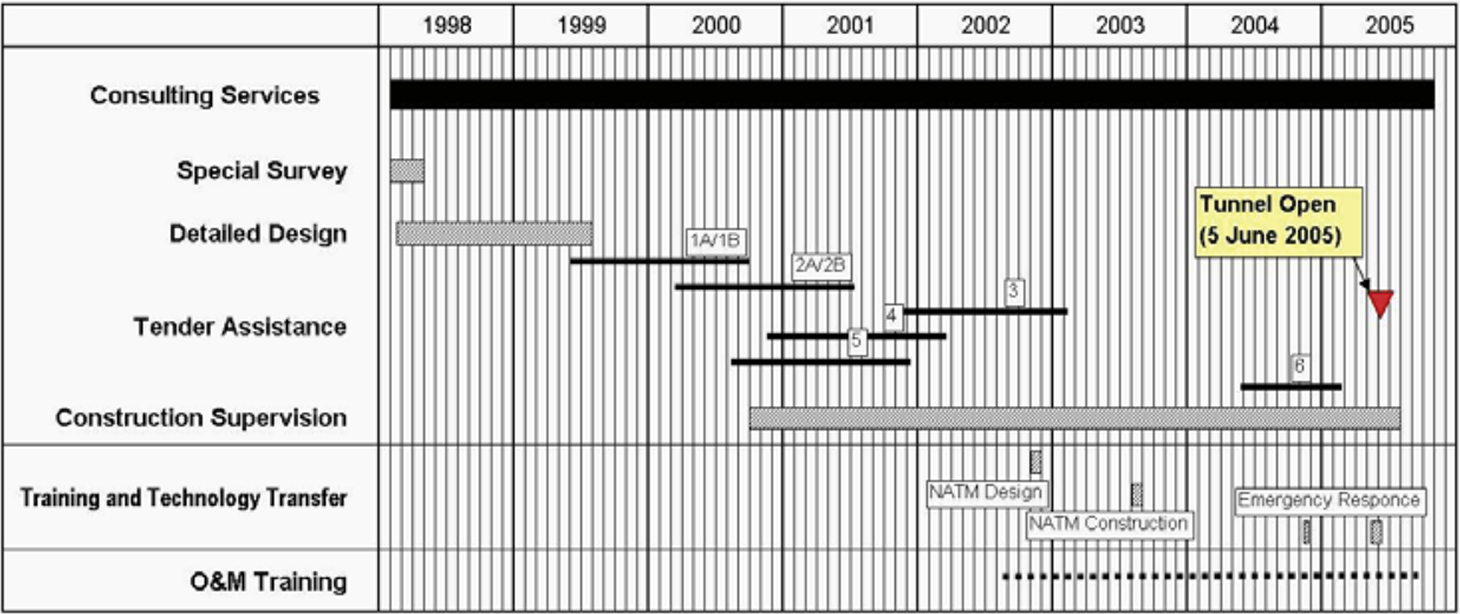

The consulting service of the project commenced in January 1998, consisting of 1) Special Survey, 2) Detailed Design, 3) Contract Tendering Assistance, 4) Construction Supervision, and 5) Training and Technology Transfer (Figure 2)

2.2Construction Works

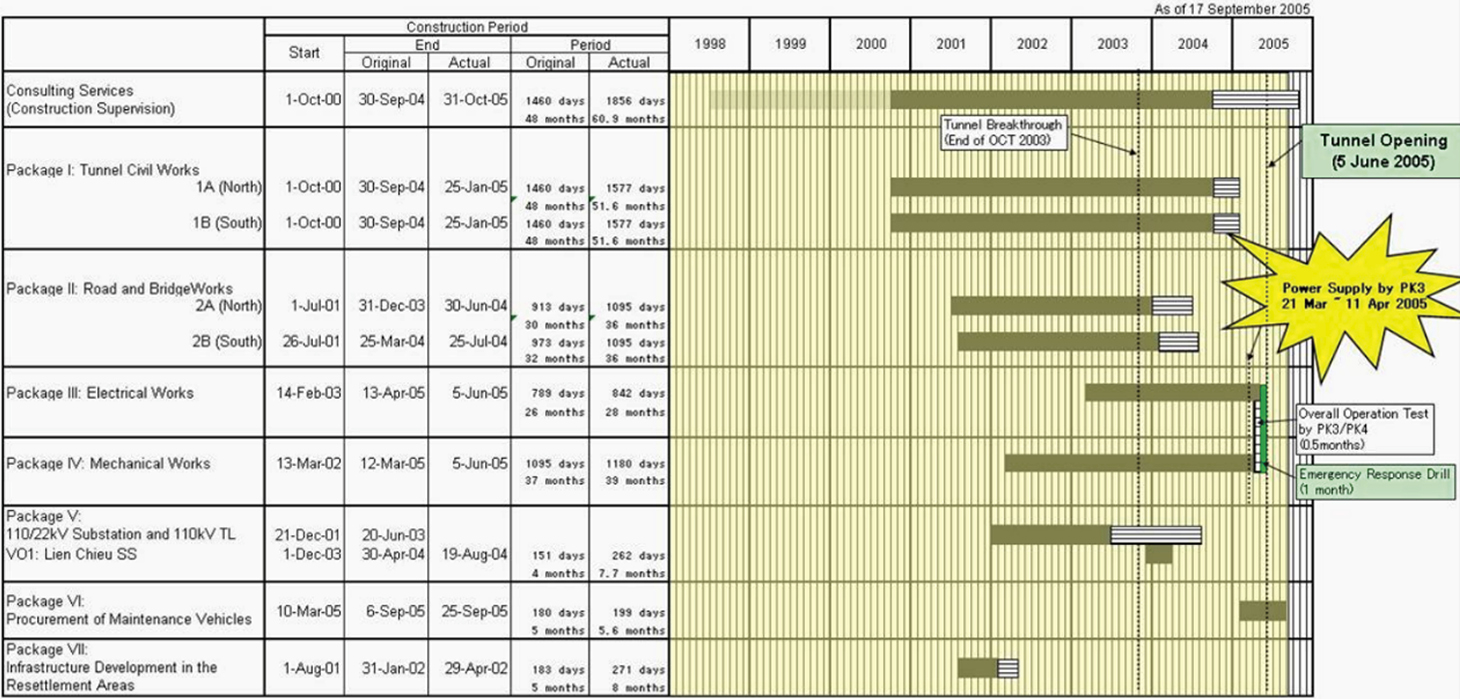

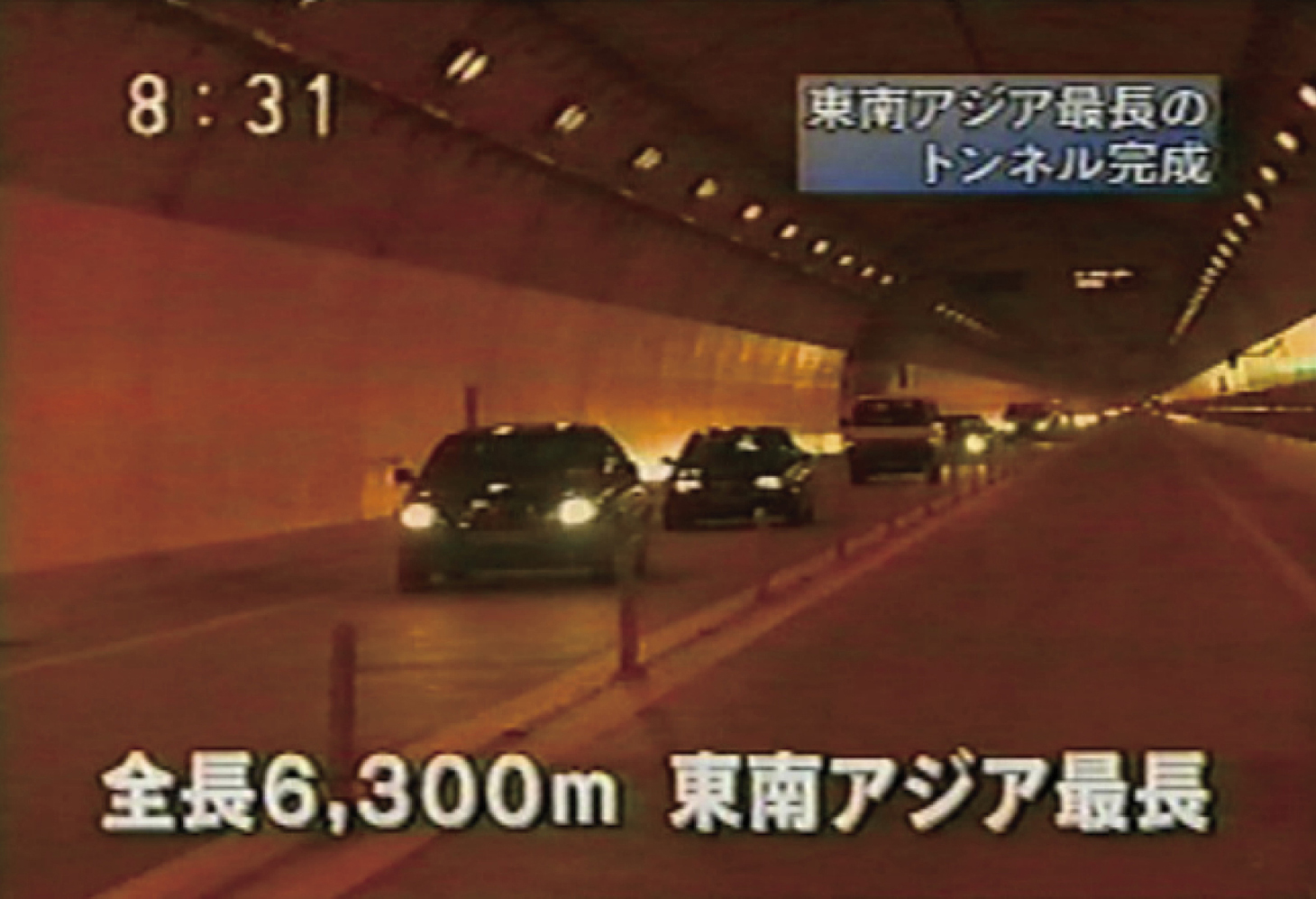

The tunnel construction started on 1st October 2000, the project had basically progressed on schedule (Figure 3), although the tunnelling works encountered some unforeseeable geological conditions (Figure 4). The tunnel traffic-opening ceremony was celebrated on 5 June 2005 (Figure 5). Since the opening, the long highway tunnel has been operated and maintained to date without any serious operational problem.

3Project Features

3.1Outline of the Project

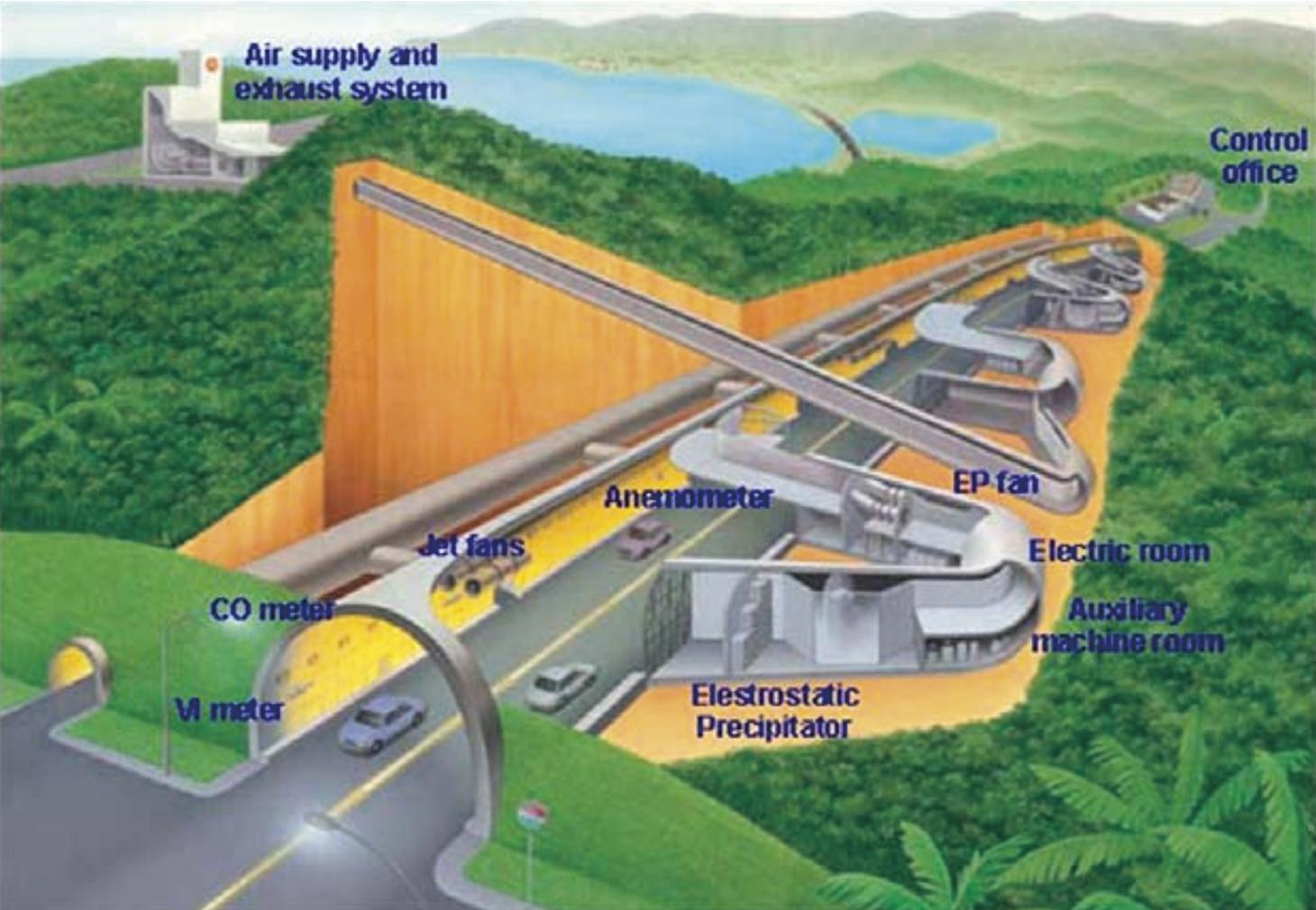

Project major features are summarized in the following (Table 2). The characteristics of project can be summarized in five (5) items; 1) 6.3km long highway tunnel, 2) 1st NATM (New Austrian Tunnelling Method) tunnel in Vietnam, 3) Longitudinal Ventilation System (Figure 2), 4) SCADA (Supervisory Control And Data Acquisition) for Overall System Control, 5) O&M Company required (Figure 6).

| 1) Project Length | 12,182m (incl. Tunnel = 6,280m, Bridges = 1,653m) |

|---|---|

| 2) Traffic Lane | 2 Lanes (Stage 1) 1.25 (shoulder) +3.75 (Carriageway) +3.75+1.25, Total 10.0m wide |

| 3) Operation System | SCADA (Supervisory Control And Data Acquisition) |

| 4) Tunnel Length | 6,280m (Main Tunnel, MT), 6,286m (Evacuation Tunnel, ET), 1,888m (Ventilation Adit, VA) |

| 5) Tunnelling Method | NATM (New Austrian Tunnelling Method) |

| 6) Cross-section | 89m2 (MT), 15.5 (ET), 36.2 (VA) |

| 7) Cross-Passage | 400m interval |

| 8) Ventilation System | Longitudinal System, 23 Jet Fans, 3 EPs, 1 VA |

| 9) Bridge Number and Length | 8 bridges, 1,653m in total length |

| 10) Toll Plazas | Two plazas on both ends of project roads |

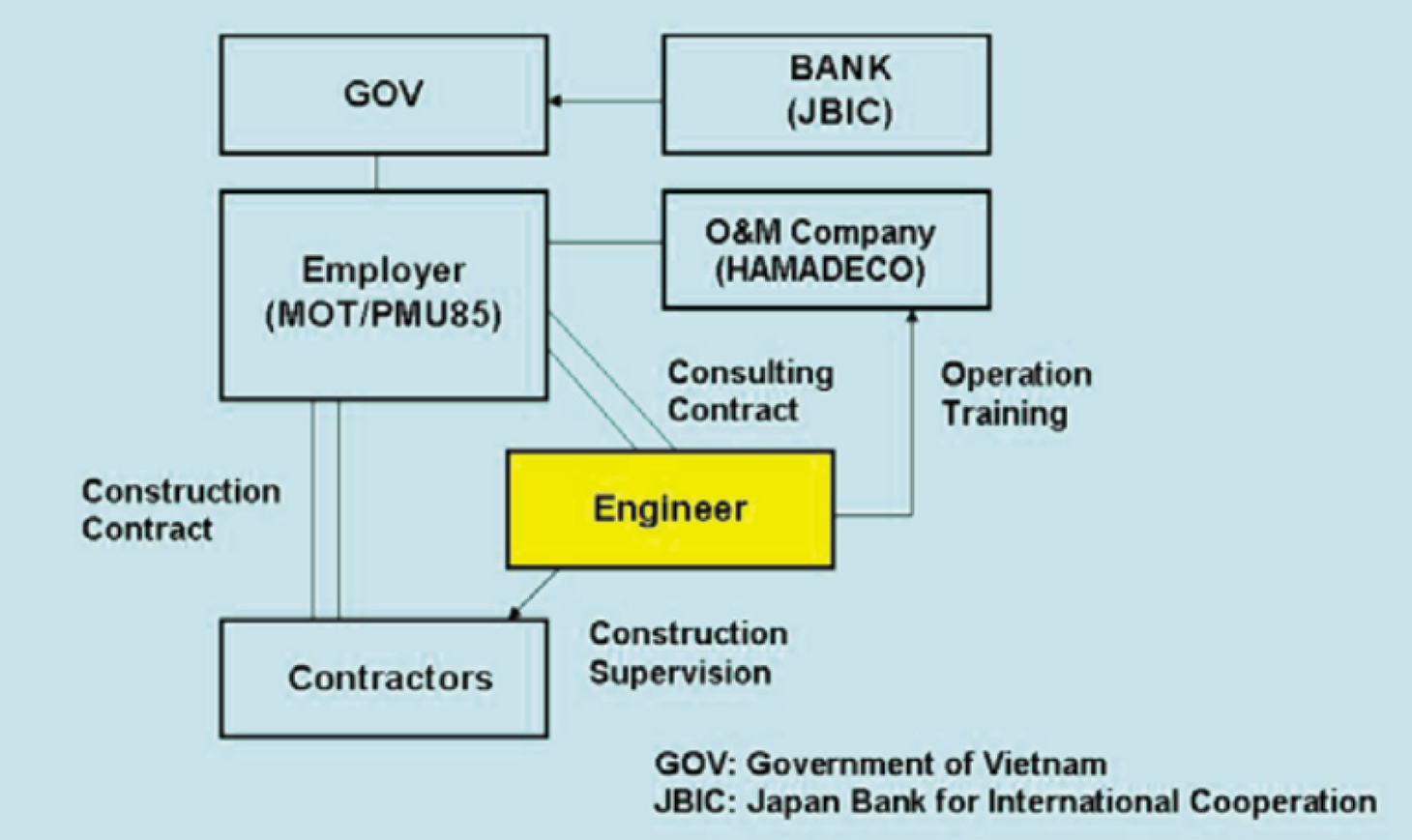

3.2Project Organization

Project organizations are summarized in the table below (Figure 7, Table 3 and Table 4).

| Financing Agency | Japan Bank for International Cooperation (JBIC) |

|---|---|

| Loan Amount | L/A No. VNIV-5, March 26, 1997, Loan Amount: JPY 5.5 billion L/A No. VNVI-5, March 30, 1999, Loan Amount: JPY 10.0 billion L/A No. VNIX-4, March 29, 2002, Loan Amount: JPY 3.359 billion (Total JPY 18.859 billion) |

| Executing Agency | Project Management Unit No. 85 (PMU85) under Ministry of Transport and Communications (MOT) |

| O&M Company | HAMADECO (HAi van tunnel MAnagement and DEvelopment COmpany) |

| Consultant | Joint Venture of Nippon Koei Co., Ltd., Japan and Louis Berger International Inc., USA in association with Transport Engineering Design Incorporation (TEDI), Vietnam |

| Contract Package | Awarded Contractor | Amount (USD) |

|---|---|---|

| 1A: Tunnel Civil Works, North Tunnel Section | JV Hazama - Cienco 6 | 43,256,000 |

| 1B: Tunnel Civil Works, South Tunnel Section | JV Dong Ah - Song Da | 27,863,000 |

| 2A: Road and Bridge Works, Lang Co Bridge Section | JV Thang Long - Truong Son | 4,633,000 |

| 2B: Road and Bridge Works, Southern Highway Section | JV Cienco 1 - Lung Lo - Vinawaco | 3,920,000 |

| 3: Electrical Works | JO of ABB - Kinden - Vinainco | 20,686,000 |

| 4: Mechanical Works | Matsushita - Itochu Consortium | 23,055,000 |

| 5: 110/22kV Substation and 110kV Transmission Line | JO of ABB - Kinden - Vinainco | 7,256,000 |

| 6: Procurement of Maintenance Vehicles | Itochu Corporation | 1,623,000 |

| 7: Infrastructure Development in the Resettlement Areas | Construction Company No. 185 | 413,000 |

| 132,705,000 | ||

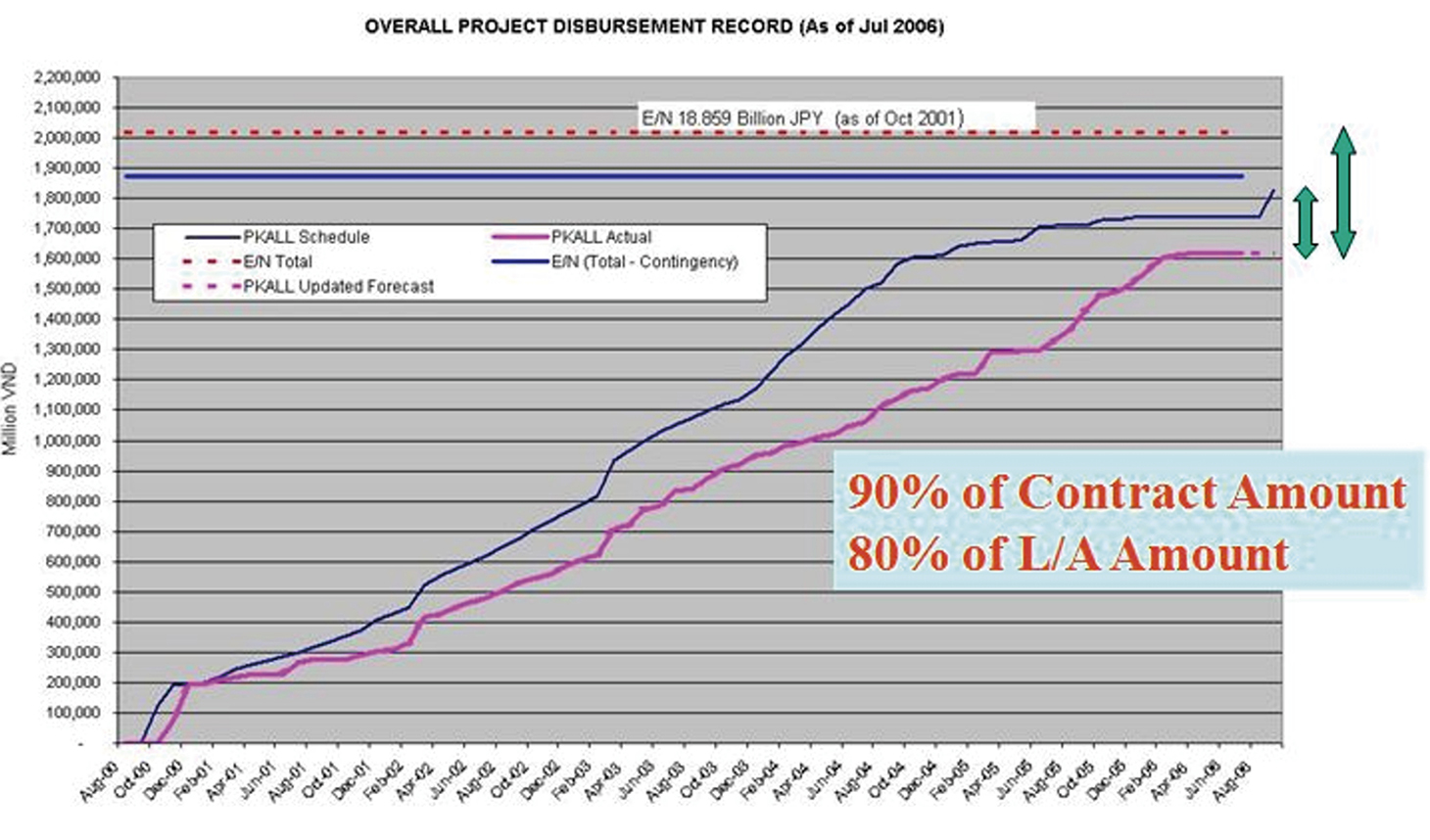

3.3Record of Disbursement

As shown in Table 2, there were three (3) loans provided by JBIC totaling 18.859 billion JPY. However, the third lone (3.359 billion JPY) was not used and returned to JBIC (Figure 8).

3.4Tunnel Emergency Training

The Consultant developed Standard Operation Plan (SOP) for the tunnel operation, and executed tunnel operation training for Vietnamese tunnel operation company that was established in April 2004. Several times of evacuation drills inside the tunnel were carried out until the fire police persuaded (Figure 9).

3.5FIDIC Based Project

The International Federation of Consulting Engineers (FIDIC) is widely used as conditions for international construction contracts. The following FIDIC conditions were used in the project (Table 5).

| Contract Package | FIDIC Conditions of Contracts |

|---|---|

| Civil Works 1A: Tunnel Civil Works, North Tunnel Section 1B: Tunnel Civil Works, South Tunnel Section 2A: Road and Bridge Works, Lang Co Bridge Section 2B: Road and Bridge Works, Southern Highway Section |

Conditions of Contract for Works of Civil Engineering Construction, PART I GENERAL CONDITIONS, 4th Edition, 1987 (Red Book) |

| Electrical and Mechanical Works 3: Electrical Works 4: Mechanical Works 5: 110/22kV Substation and 110kV Transmission Line |

Conditions of Contract for Electrical and Mechanical Works, 3rd Edition, 1987 (Yellow Book) |

3.6Monthly Progress Tracking Report

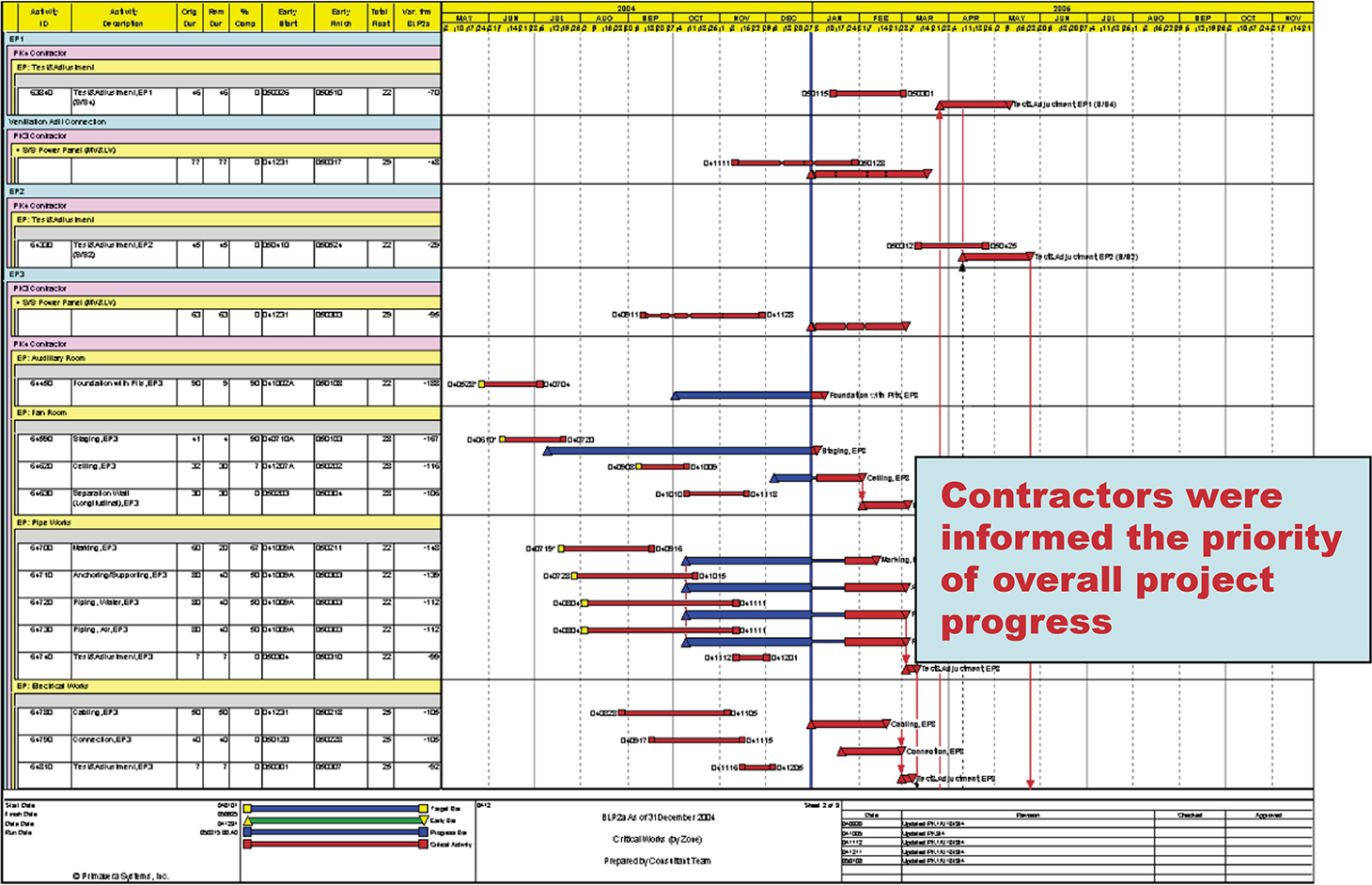

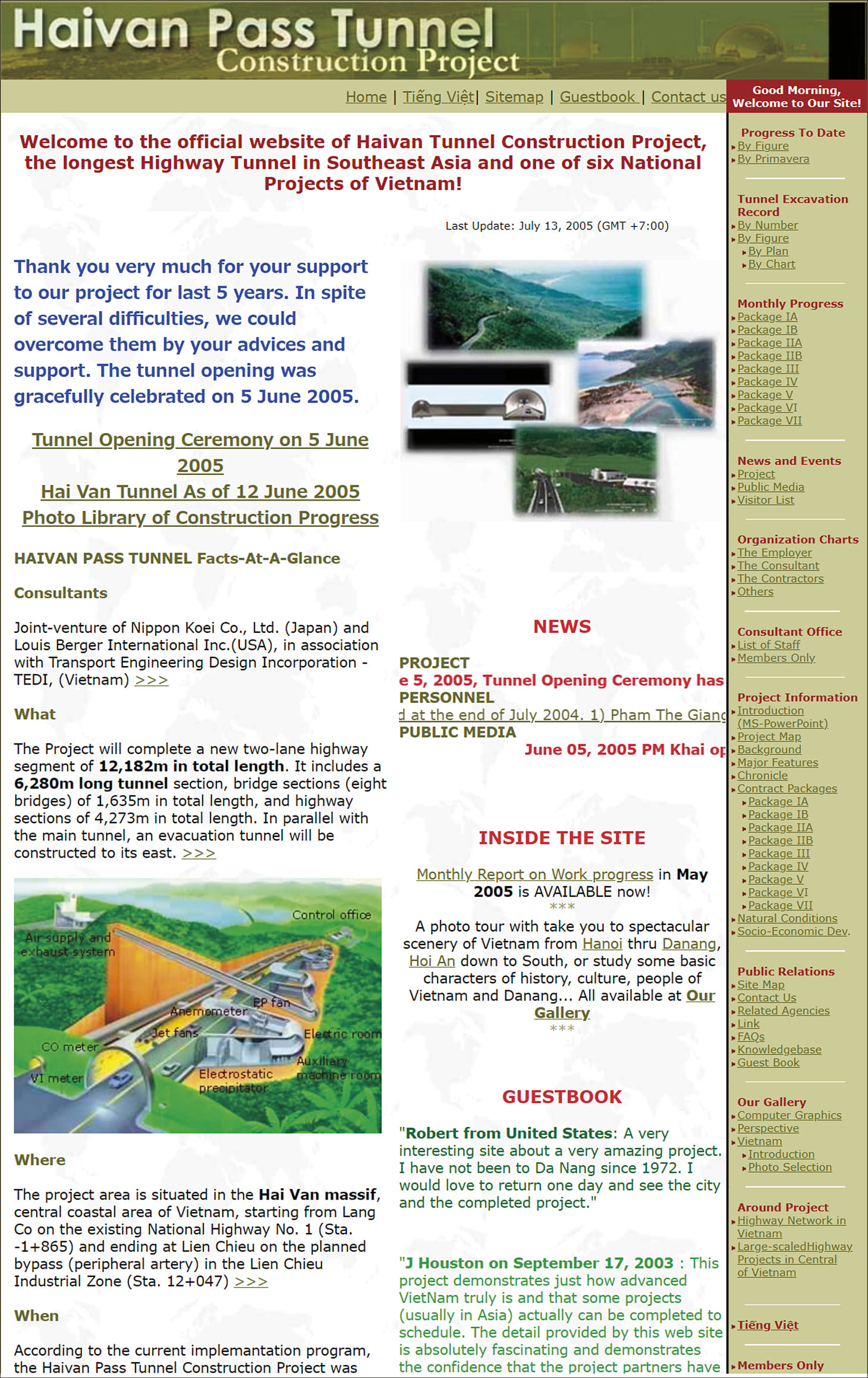

Work Breakdown Structure (WBS) was developed for the tunnel civil works, the electrical works and the mechanical works in order to establish the Critical Path Method (CPM) scheduling by utilizing Primavera P3. Since April 2004, the consultant had issued a “Monthly Progress Tracking Report” to the Employer, copied to the contractors, informing of 1) Change of WBS and work linkage during the previous month, 2) Overall progress of the project (summary), 3) Critical works (TF < 30 days), 4) Site hand-over and Energization Forecast, 5) The report was also presented at URL:https://haivantunnel.com/05_progresstodate/work.htm (Figure 10 and Figure 11).

4Lessons Leaned

4.1Communication Management with Clear RAM

As emphasized in the Project Management Body of Knowledge (PMBOK), the communication management is the most important management area for successful project implementation.

The Responsibility Assignment Matrix (RAM) should be considered in the project. It could reduce unnecessary communication barriers among the people in the project, especially projects in the developing countries. All the stakeholders should respect the difference of culture in the project, and disclose RAM at the same time, and it surely makes him/her contribute to the project success (Table 6).

4.2Time Management with WBS

Time is the most important target in the construction project in changes that should be kept traceable in the project to avoid unnecessary Extension Of Time (EOT) claim, which multiple contractors are involved in. An effective monitoring unit should be established for overall work coordination. The PMBOK recommends a unit equivalent to about 80 working hours; however, physical working areas for 80 hours are usually very different in civil works and electrical and mechanical works. It is requested to establish acceptable work units for each contractor, and such an agreed unit should be used in the process of WBS development.

Milestone in the project, especially hand-over and hand-back between the contractors, should be clearly indicated in the WBS and the monitoring schedule. Progressive detailing of the schedule can be made when a milestone is realized; however, such configuration changes should be kept traceable in the project to avoid unnecessary EOT claims.

4.3Utilization of Web, as Communication Tool, in PMO

The Author reported that there were four objects for IT management in the Project Management Office (PMO); 1) Office Infrastructure, 2) Work Tools, 3) Data Management, and 4) Web, and he had been updating on the innovative application of the Web technology for the project management.

The Author proposed standardized contents of Project Office WEBsite (POWEB), including modules of public, project-consultant, project-coordination, company, etc. Please visit the site below for more details. URL:https://haivantunnel.com (Figure 12).

(URL:https://haivantunnel.com/)

- 1) FIDIC, International Federation of Consulting Engineers, http://www.fidic.org/

- 2) I. Ishimoto (2001), A Basic Understanding of IT Management Required at Overseas Project, Nippon Koei Technical Bulletin (21), 233-239

- 3) I. Ishimoto (2002), Introduction of IT Management in Construction Supervision Project, Nippon Koei Technical Bulletin (22), 207-213

- 4) I. Ishimoto (2003), A Study on Website for Construction Supervision Project, Nippon Koei Technical Bulletin (23), 143-151

- 5) I. Ishimoto (2004), Introduction of Hai Van Pass Tunnel Construction Project in Vietnam, Proceedings of 3rd CECAR, Seoul, August 16 -18

- 6) I. Ishimoto (2004), Introduction of Project Management Practice for Construction Supervision of A Long Highway Tunnel, Nippon Koei Technical Forum (12), 91-103

- 7) I. Ishimoto (2005), Introduction of Hai Van Pass Tunnel Construction Project in Vietnam, Proceedings of 2005 PMI Global Congress, Singapore, Feb 21-23

- 8) I. Ishimoto (2005), Introduction of Hai Van Pass Tunnel Construction Project in Vietnam, Proceedings of 15th International Road Federation World Meeting, Bangkok, June 14-18

- 9) I. Ishimoto (2005), Introduction of Project Management Practice for Construction Supervision of A Long Highway Tunnel (2), Nippon Koei Technical Forum (13), 83-99

- 10) I. Ishimoto (2006), A Review of Success Factors in Project Management of ODA Construction Projects, Nippon Koei Technical Forum (14), 69-79

- 11) I. Ishimoto (2006), PROJECT MANAGEMENT FOR HAI VAN TUNNEL CONSTRUCTION PROJECT IN VIETNAM, REAAA 12th Conference, Manila

- 12) PMI (2003), The Construction Extension to A Guide to the Project Management Body of Knowledge (PMBOKョ Guide) 2000 Edition, http://www.pmi.org/

- 13) Primavera Systems, Inc., http://www.primavera.com/

Author

Ichizuru ISHIMOTO

Born in 1961, he completed a master’s degree in the Faculty of Engineering at Kanazawa University in March 1988.

In April 1988, he joined the transportation engineering department of Nippon Koei Co., Ltd.

In August 2000, he joined the Hai Van Tunnel Construction Project as Construction Engineer/Resident Engineer.

In February 2002, he was promoted as Project Manager and completed the project timely in quality.

In May 2005, Hai Van Tunnel was officially open to the public.

His achievements were highly appreciated, and he received “President Award” at the tunnel-breakthrough ceremony in October 2003 and “Prime Minister Award” at the opening ceremony in May 2005.

After the project completion, he joined several road tunnel projects in Vietnam, like Deo Ca Tunnel (2017), Danang Tunnel (2018), Cu Mong Tunnel (2019), 2nd Hai Van Tunnel (2021), as project manager.