|

Reader's Voice |

|

PDF Version is available: Click here |

The bond strength and bond-slip behavior between reinforcing steel and concrete have been extensively studied over the last few decades. Studies have shown that the bond strength depends on many factors including the properties of the concrete and steel, the surface deformation of the bars, the loading history, the casting position of the bar, and the confinement level.

For large-diameter bridge columns and piles, the use of reinforcing bars with diameters greater than 36 mm is common. However, data on the bond strength and bond stress-slip relation of these large-diameter bars are scarce. The development length requirements in ACI 318 and AASHTO LRFD Specifications are largely based on experimental data obtained from 36-mm and smaller bars, and they do not allow lap-splicing of bars larger than 36 mm because of the lack of experimental data. In recent years, some pullout and lap-splice tests were conducted on large-diameter bars. These studies have shown that the bond strength tended to decrease significantly with the increase of the bar size for unconfined bar-slip test specimens. For well confined specimens, the effect of the bar size on bond strength was negligible. However, all these tests were carried out under monotonically increasing slip. No data are available on the cyclic bond-slip behavior of large-diameter bars.

Under the support of the California Department of Transportation, a study is being conducted at UCSD to characterize the bond-slip behavior of large-diameter (36, 45, 58 mm) bars subjected to monotonic and cyclic loadings with an ultimate goal of accurately identifying the minimum development length required for longitudinal column reinforcement of any size extended into an enlarged CIDH pile. With the pile diameter at least 610 mm larger than that of the column in such construction, the column reinforcement extended into the pile can be perceived as forming a non-contact splice with the pile reinforcement. This creates additional uncertainty about the adequate development/splice length. For large-diameter bridge columns, minimizing the splice or development length required for the longitudinal reinforcement can lead to substantial savings in construction costs and efforts. This study includes basic bond-slip and bar pullout experiments as well as detailed nonlinear finite element modeling of the bond-slip behavior in column-shaft assemblies. In the bond-slip and bar pullout tests, the specimens were well confined to simulate the condition in a pile. A cyclic bond-slip model has been developed and calibrated with results of these tests. It has been implemented as a concrete-steel interface element in ABAQUS for the finite element analysis of column-shaft assemblies. Finally, four full-scale column-shaft assemblies are being tested in the Charles Lee Powell Structural System Laboratory at UCSD to validate the new design recommendations and finite element models developed in this study. The columns have a diameter of 1.2 m while the pile diameter is 1.8 m.

Photo.1 Full-scale column-pile assembly test |

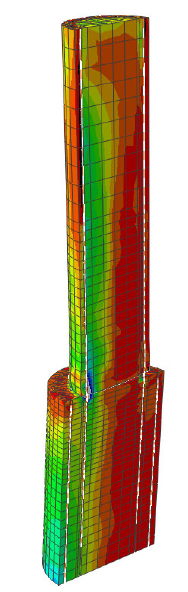

Fig.1 Finite element model with ABAQUS |

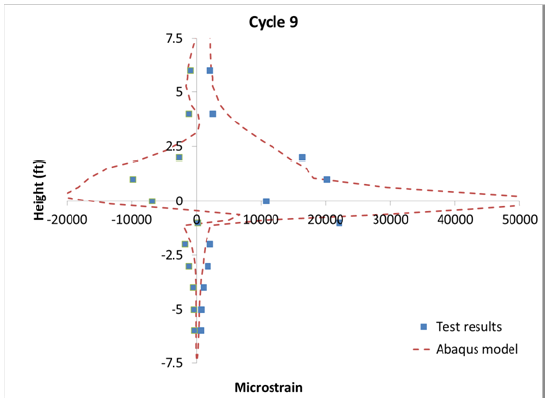

Fig.2 Comparison of bar strains from test and analysis |

|